Company

Innovationat at its best

Our Heritage

A Legacy of Innovation

Rooted in the ancient city of Tus, Iran, TGT’s history is deeply intertwined with the principles of efficient heat transfer. The region has a rich heritage of innovative heating systems, most notably exemplified by the ancient bathhouse built in 1615 AD. This architectural marvel showcased advanced heating techniques for its time, underlining the region’s pioneering spirit in thermal engineering.

The Mehdi Qoli Beg bathhouse, located in the historic city of Tus, Iran, is renowned for its cutting-edge underfloor heating system. Constructed in 1615 AD, this ancient bathhouse employed sophisticated heating techniques that were well ahead of its time. The bathhouse’s underfloor heating system, rooted in the principles of efficient heat transfer, is a prime example of the region’s advanced thermal engineering knowledge.

TGT’s Journey

Inspired by this historical legacy, TGT was founded in 2009 with a vision to continue this tradition of innovation. Since its inception, TGT has been at the forefront of developing advanced heat transfer solutions. Key milestones in our journey include:

Get to know Plate Heat Exchanger

First PHE in Mid-east

As the first company in Iran and the Middle East to manufacture heat exchangers in 2001, TGT has been at the forefront of thermal technology. Our commitment to innovation has driven us to develop cutting-edge solutions for a wide range of industries.

First PHE Design in Mid-east

TGT holds the distinction of being the first company in Iran and the Middle East to patent wide-plate heat exchanger design and manufacturing. This groundbreaking technology has set new standards in efficiency and performance.

First 2500 ton hot hydraulic press

In 2015, TGT made history by introducing a 2500-ton press, the first of its kind in the Middle East. This state-of-the-art equipment allows us to produce high-quality heat exchangers with unmatched precision and efficiency.

350 Types of plates

With an extensive range of over 350 types of heat exchanger plates, TGT offers customized solutions to meet the unique requirements of every industry. Our commitment to product diversity ensures that you find the perfect heat exchanger for your application.

Why TGT in heat transfers ?

Mission

From start to finish, TGT guarantees the quality of every single part, produced in-house.

Vision

TGT is the Middle East’s leading manufacturer of PHEs, setting new standards in both production volume and technology.

Value

Quality: We are committed to delivering products and services of the highest quality.

Customer Satisfaction: We strive to exceed customer expectations through exceptional service.

.

Innovation: We continuously push the boundaries of technology to develop innovative solutions.

Sustainability: We are dedicated to minimizing our environmental impact and promoting sustainable practices.

Value

Quality

We are committed to delivering products and

Innovation

We continuously push the boundaries of technology to develop innovative solutions.

Customer Satisfaction

We strive to exceed customer expectations through exceptional service.

Sustainability

We are dedicated to minimizing our environmental impact and promoting sustainable practices.

Expertise

Knowledge-Based Company:

Trusted company with an experienced, academic, and expert management

TGT Co. was recognized as the only knowledge-based company in the designing and manufacturing of plate heat exchangers in 2013 with the approval of special government professional groups. TGT Co is the only manufacturing company that designs and manufactures all types of plate heat exchangers in the Middle East region. We have designed and manufactured more than 15 types of knowledge-based products in recent years.

Innovative Solutions:

...

At TGT, innovation is more than just a buzzword; it’s the driving force behind everything we do. Our commitment to research and development is unwavering, as we continually strive to push the boundaries of heat transfer technology. This dedication has led to the development of a wide range of innovative products, from highly efficient plate heat exchangers to specialized pumps and valves. By investing in cutting-edge research and fostering a culture of creativity, TGT is able to anticipate and address the evolving needs of our customers.

25.000 ton Press

Design and manufacturing of large PHEs with high heat transfer capacity and large flowing volumes requires forming of large sheet metals more than 4.5 meters in length. We are the only company in the Middle East capable of producing such large PHE units with the largest and most unique hydraulic press in the region having a tonnage of 25,000 tons. This press can form five sheets simultaneously. In addition, TGT Co. has a wide range of other high-tonnage presses to form PHE sheets.

Capabilities

Special Industrial equipments.

6

Laser welding and cladding equipment

20

Special laboratory equipment

35

Machining equipment

10

Hot high-tonnage hydraulic presses

8

High-tonnage hydraulic presses

20

CNC machines

140

Special manufacturing equipment

6

Laser welding and cladding equipment

20

Special laboratory equipment

35

Machining equipment

10

Hot high-tonnage hydraulic presses

8

High-tonnage hydraulic presses

20

CNC machines

140

Special manufacturing equipment

TGT Sites

Center of Innovative Technologies (CIT)

Plate heat exchanger production and assembly Site

R&D - separation projects Site

Gasket compounding and production factory

Headquarter and engineering office

Administrative and sales office

Services and repair Center

Painting and cutting Site

Research and development hub for academia and industry

laboratory

Heat exchanger performance laboratory

Heat exchanger performance laboratory

During the designing and manufacturing of a plate heat exchanger, after numerical analysis and designing a new product (new design of plates and gasket), a prototype is manufactured and the performance is tested under actual operating conditions. TGT has established a one-of-a-kind industrial research-based laboratory for testing the performance and energy efficiency of heat exchangers. TGT’s heat exchanger laboratory is the only heat exchanger performance laboratory in the country to be certified with ISO 17025.

Polymer and rubber laboratory

Polymer and rubber laboratory

TGT’s specialized polymer and rubber laboratory is established to control the quality parameters and also expand the variety of polymer products in the oil, gas, and petrochemical industries. This laboratory has gained the ISO 17025 certificate by taking advantage of faculty members, expert engineers, and advanced testing devices based on national and international standards including the most practical tests of the polymer and rubber industries. The laboratory has special equipment to determine the life of PHE gaskets in order to improve their lifetime.

Metallography and non-destructive testing laboratory

Metallography and non-destructive testing laboratory

Different types of manufacturing processes like machining, welding, cladding required metallography and microscopic examining to achieve the desired properties of alloys and metals such as toughness, hardness, and tensile strength. To ensure the quality of manufactured parts, non-destructive testing is inevitable. For this purpose, the metallography and non-destructive testing (NDT) laboratory has been equipped and can perform different metallography and non-destructive testing services. This laboratory has also received the ISO 17025 certificate because of its specialized expertise and equipment.

Software Solutions

TIP ® Taha Intelligence Platform

Real-time process monitoring and analysis of PHEs

TGT SheetCut ®

Optimized sheet cutting for minimal waste

TGT ProjectTrack ®

Comprehensive project management and document tracking

TGT DocAuto ®

Automated documentation for enhanced efficiency

TGT PHE-Design Software ®

Tailored plate heat exchanger design for optimal performance

Taha - SEP ®

Advanced flow simulation for mist eliminators

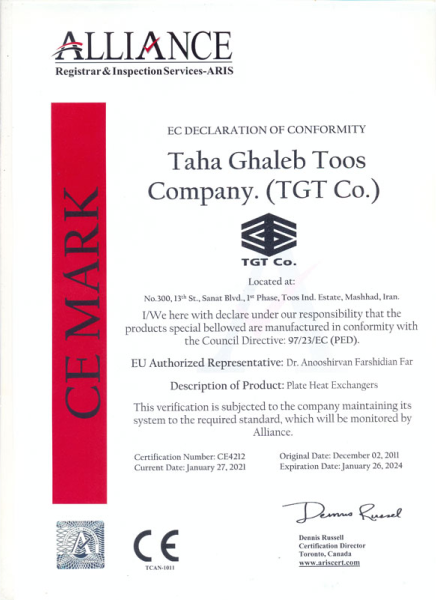

Standards and Certifications

ISO 45001

ISO 9001

ISO 14001

CE4212

Sustainability

Innovating for a Greener Tomorrow

TGT is at the forefront of developing innovative solutions that address global environmental challenges. By leveraging cutting-edge technology and sustainable materials, we are able to create products that are both efficient and environmentally friendly. Our commitment to research and development ensures that we are continually exploring new ways to reduce our carbon footprint and promote sustainability

The Brains Behind

Dr. Anooshiravan Farshidianfar

Chief Executive Officer (CEO), Professor of Mechanical Engineering at Ferdowsi University of Mashhad.

Kooresh Farshidianfar

Chief Marketing Officer (CMO) Member of The Board

Alireza Ghasemi

Chairman of The Board (COB) Chief Financial Officer (CFO)

Hossein Khatibi

Chief Operating Officer (COO) Member of The Board

Dr. Alireza Farshidianfar

Chief Manufacturing Officer Member of The Board

Dr. Ardeshir Farshidianfar (1962-2020)

Dr. Farshidianfar was the co-founder, board member and chief technology officer (CTO) of TGT co. from 2000 to 2020. He pioneered the design and manufacturing of plate heat exchangers in Iran. He was awarded the entrepreneur and engineer of the year of the year award in 2013. The results of Dr. Farshidianfar’s insightful work have been published in 14 books, numerous journal papers and conference proceedings.