Strand Pelletizing

Strand Pelletizing

System

Function

How It Works and operation

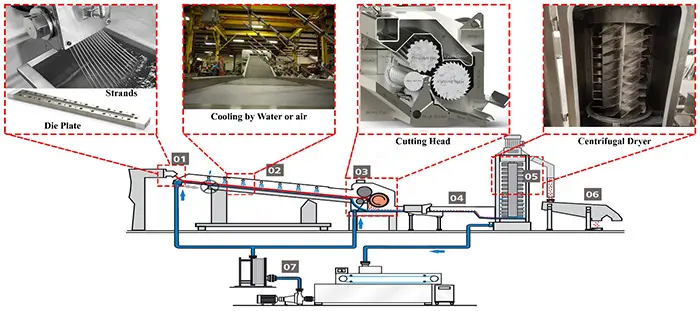

The underwater strand pelletizing system transforms molten polymer into uniform pellets. Molten polymer is extruded through a die plate, forming strands that are then submerged in a water bath for cooling. These strands are fed into a cutting head, where they are sliced into pellets by a cutting rotor. Subsequent steps involve cooling, drying, and separating the pellets. The system incorporates a continuous filtration and cooling process for the water.

Specifications

Die Plate and Knife Cutter Specifications

TGT Company designs and optimizes underwater pelletizing systems tailored to the specifications of the produced granules, the production capacity, and the variable environmental conditions of the product.

Materials and Construction

Feed Rolls:

These are responsible for feeding the polymer strands into the cutting zone. They are typically made of:

- Stainless steel (AISI 316, 316Ti, 440C, 420, 431)

- Polyurethane Rubber (NBR, polyurethane)

- Chromium-plated steel

The type of material used depends on the specific application and the type of polymer being processed.

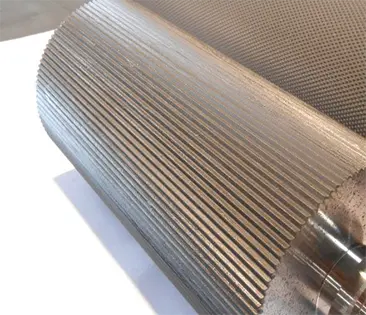

Cutting Rotor

This component slices the polymer strands into pellets. It is typically made of:

- Stellite: A cobalt-based alloy known for its excellent wear resistance and corrosion resistance.

- Hardened stainless steel: Offers a good balance of hardness and toughness.

- Carbide: A very hard material that provides exceptional wear resistance.

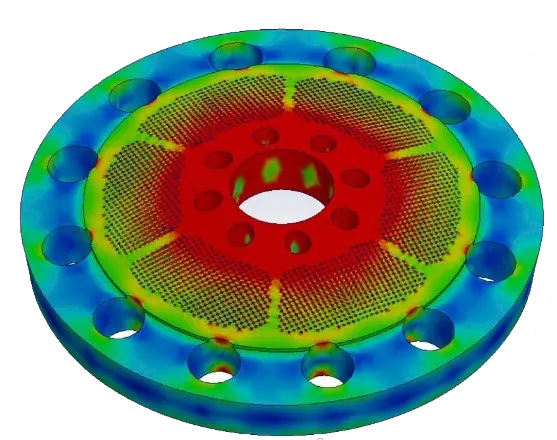

Die Plate

This component shapes the polymer melt into strands. It is typically made of:

Stainless steel (AISI 431, 420)

The die plate design is crucial for determining the shape and size of the pellets.

Other Components

Water Bath: Used to cool the polymer strands.

Drying System: Removes moisture from the pellets.

Pumps and Filters: Circulate and filter the water used in the process.

The materials used in the construction of these components are carefully selected to ensure optimal performance, durability, and efficiency. TGT’s expertise in material selection and manufacturing processes enables them to produce high-quality pelletizing systems that meet the specific needs of their customers

TGT Innovations

TGT Innovations

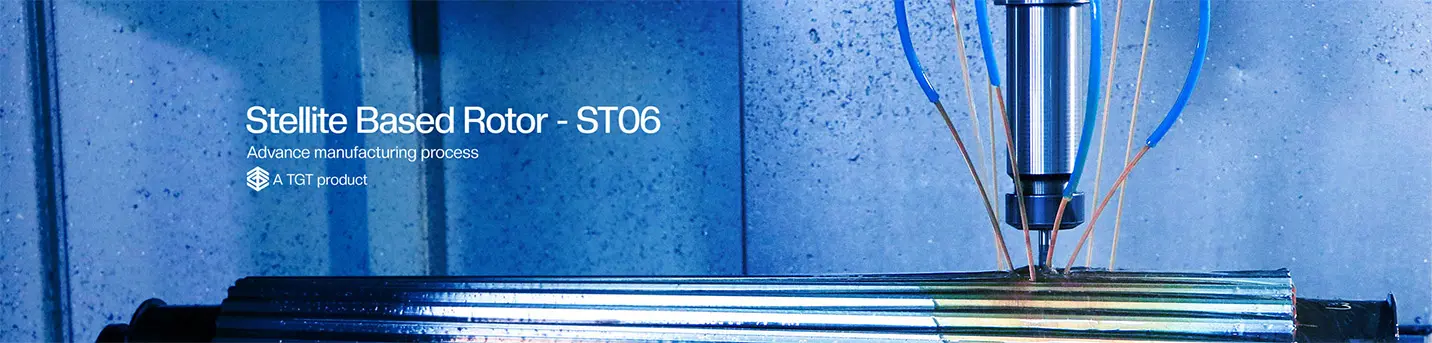

TGT has introduced several innovations in the design and manufacturing of die plates, knife cutters and cutting rotors. These include the use of vacuum brazing

laser cladding , simulation software, and advanced machining techniques. Their products are tailored to specific polymer types and offer high thermal stability.

Competitive Advantages

TGT Competitive Edge

TGT’s products offer several competitive advantages, including:

Long lifespan: Due to the use of advanced materials and manufacturing techniques.

Customizable: Products can be tailored to specific polymer types.

High-performance materials: TGT uses advanced composite materials reinforced with titanium carbide and tungsten carbide.

Advanced manufacturing: TGT employs state-of-the-art CNC machining.