طاها قالب

نوآوری در بهترین حالت خود.

میراث ما

میراثی از نوآوری.

ریشهدار در شهر باستانی توس، ایران، تاریخچه طاها قالب عمیقاً با اصول انتقال حرارت کارآمد در هم آمیخته است. این منطقه میراث غنی از سیستمهای گرمایشی نوآورانه دارد که برجستهترین نمونه آن حمام باستانی ساخته شده در سال 1615 میلادی است. این شگفتی معماری، تکنیکهای گرمایشی پیشرفتهای را برای زمان خود به نمایش گذاشت و بر روحیه پیشگام منطقه در مهندسی حرارتی تأکید کرد.

حمام مهدی قلی بیگ، واقع در شهر تاریخی توس ایران، به دلیل سیستم گرمایش از کف پیشرفته خود مشهور است. این حمام باستانی که در سال 1615 میلادی ساخته شده است، از تکنیکهای گرمایشی پیچیدهای استفاده میکرد که بسیار پیشرفتهتر از زمان خود بود. سیستم گرمایش از کف حمام، که ریشه در اصول انتقال حرارت کارآمد دارد، نمونهای بارز از دانش پیشرفته مهندسی حرارتی منطقه است.

سفر طاها قالب

با الهام از این میراث تاریخی، طاها قالب در سال 2009 با چشمانداز ادامه این سنت نوآوری تاسیس شد. از بدو تاسیس، طاها قالب در خط مقدم توسعه راه حلهای پیشرفته انتقال حرارت قرار داشته است. نقاط عطف کلیدی در سفر ما عبارتند از:

Get to know Plate Heat Exchanger

اولین مبدل حرارتی صفحهای در خاورمیانه

طاها قالب به عنوان اولین شرکت در ایران و خاورمیانه که در سال 2001 به تولید مبدلهای حرارتی پرداخت، در خط مقدم فناوری حرارتی قرار داشته است. تعهد ما به نوآوری، ما را به توسعه راه حلهای پیشرفته برای طیف گستردهای از صنایع سوق داده است.

اولین طراحی مبدل حرارتی صفحهای در خاورمیانه

طاها قالب این تمایز را دارد که اولین شرکت در ایران و خاورمیانه است که طراحی و ساخت مبدل حرارتی صفحهای عریض را به ثبت رسانده است. این فناوری پیشگامانه استانداردهای جدیدی را در کارایی و عملکرد تعیین کرده است.

اولین پرس هیدرولیک گرم 2500 تنی

در سال 2015، طاها قالب با معرفی یک پرس 2500 تنی، اولین نوع خود در خاورمیانه، تاریخساز شد. این تجهیزات پیشرفته به ما امکان میدهد مبدلهای حرارتی با کیفیت بالا را با دقت و کارایی بینظیر تولید کنیم.

350 نوع صفحه

طاها قالب با طیف گستردهای از بیش از 350 نوع صفحه مبدل حرارتی، راه حلهای سفارشی را برای برآورده کردن نیازهای منحصر به فرد هر صنعت ارائه میدهد. تعهد ما به تنوع محصول تضمین میکند که مبدل حرارتی مناسب برای کاربرد خود را پیدا کنید.

Why TGT in heat transfers ?

ماموریت

طاها قالب از ابتدا تا انتها کیفیت تک تک قطعات تولید شده در داخل شرکت را تضمین میکند.

چشم انداز

طاها قالب تولید کننده پیشرو مبدلهای حرارتی صفحهای در خاورمیانه است که استانداردهای جدیدی را در حجم تولید و فناوری تعیین میکند.

ارزشها

کیفیت: ما متعهد به ارائه محصولات و خدمات با بالاترین کیفیت هستیم.

رضایت مشتری: ما تلاش میکنیم با ارائه خدمات استثنایی، انتظارات مشتری را فراتر بگذاریم.

.

نوآوری: ما به طور مداوم مرزهای فناوری را برای توسعه راه حلهای نوآورانه جابجا میکنیم.

پایداری: ما متعهد به به حداقل رساندن اثرات زیست محیطی خود و ترویج شیوههای پایدار هستیم.

Value

Quality

We are committed to delivering products and

Innovation

We continuously push the boundaries of technology to develop innovative solutions.

Customer Satisfaction

We strive to exceed customer expectations through exceptional service.

Sustainability

We are dedicated to minimizing our environmental impact and promoting sustainable practices.

تخصص

شرکت دانشبنیان:

شرکتی قابل اعتماد با مدیریتی مجرب، دانشگاهی و متخصص.

شرکت طاها قالب در سال 2013 با تأیید گروههای تخصصی ویژه دولتی، به عنوان تنها شرکت دانشبنیان در طراحی و ساخت مبدلهای حرارتی صفحهای شناخته شد. شرکت طاها قالب تنها شرکت تولیدی است که تمامی انواع مبدلهای حرارتی صفحهای را در منطقه خاورمیانه طراحی و تولید میکند. ما در سالهای اخیر بیش از 15 نوع محصول دانشبنیان طراحی و تولید کردهایم.

8

همکاری دانشگاههای بینالمللی

راه حلهای نوآورانه:

پیشرو در فناوری انتقال حرارت

در طاها قالب، نوآوری چیزی فراتر از یک شعار است. این نیروی محرکه پشت تمام کارهایی است که انجام میدهیم. تعهد ما به تحقیق و توسعه تزلزل ناپذیر است، زیرا ما دائماً در تلاش برای پیشبرد مرزهای فناوری انتقال حرارت هستیم. این تعهد منجر به توسعه طیف گستردهای از محصولات نوآورانه، از مبدلهای حرارتی صفحهای بسیار کارآمد گرفته تا پمپها و شیرآلات تخصصی شده است. طاها قالب با سرمایهگذاری در تحقیقات پیشرفته و پرورش فرهنگ خلاقیت، قادر است نیازهای در حال تحول مشتریان خود را پیشبینی و برطرف کند.

پرس 25000 تنی

طراحی و ساخت مبدلهای حرارتی صفحهای بزرگ با ظرفیت انتقال حرارت بالا و حجم جریان زیاد، نیاز به شکلدهی ورقهای فلزی بزرگ با طول بیش از 4.5 متر دارد. ما تنها شرکتی در خاورمیانه هستیم که قادر به تولید چنین واحدهای مبدل حرارتی صفحهای بزرگی با بزرگترین و منحصر به فردترین پرس هیدرولیک منطقه با تناژ 25000 تن هستیم. این پرس میتواند پنج ورق را به طور همزمان شکل دهد. علاوه بر این، شرکت طاها قالب طیف گستردهای از پرسهای تناژ بالای دیگر را برای شکلدهی ورقهای مبدل حرارتی صفحهای در اختیار دارد.

قابلیتها

تجهیزات صنعتی ویژه.

6

تجهیزات جوش و روکش لیزری

20

تجهیزات آزمایشگاهی ویژه

35

تجهیزات ماشینکاری

10

پرسهای هیدرولیک گرم با تناژ بالا

8

پرسهای هیدرولیک با تناژ بالا

20

دستگاههای CNC

140

Special manufacturing equipment

6

تجهیزات جوش و روکش لیزری

20

تجهیزات آزمایشگاهی ویژه

35

تجهیزات ماشینکاری

10

پرسهای هیدرولیک گرم با تناژ بالا

8

پرسهای هیدرولیک با تناژ بالا

20

دستگاههای CNC

140

Special manufacturing equipment

مکانهای طاها قالب

مرکز فناوریهای نوآورانه (CIT)

سایت تولید و مونتاژ مبدلهای حرارتی صفحهای

سایت تحقیق و توسعه - پروژههای جداسازی

کارخانه ترکیب و تولید واشر

دفتر مرکزی و مهندسی

دفتر اداری و فروش

مرکز خدمات و تعمیرات

سایت رنگآمیزی و برش

قطب تحقیق و توسعه برای دانشگاه و صنعت

آزمایشگاه

آزمایشگاه عملکرد مبدل حرارتی

آزمایشگاه عملکرد مبدل حرارتی

در فرآیند طراحی و ساخت مبدل حرارتی صفحهای، پس از تحلیلهای محاسباتی و طراحی یک محصول جدید (شامل طراحی جدید صفحات و واشرها)، یک نمونه اولیه ساخته میشود و عملکرد آن در شرایط عملیاتی واقعی آزمایش میگردد. طاها قالب یک آزمایشگاه تحقیقاتی صنعتی منحصر به فرد برای سنجش عملکرد و بازده انرژی مبدلهای حرارتی راهاندازی کرده است. آزمایشگاه مبدل حرارتی طاها قالب تنها آزمایشگاه عملکرد مبدل حرارتی در کشور است که موفق به دریافت گواهینامه ISO 17025 شده است.

آزمایشگاه پلیمر و لاستیک

آزمایشگاه پلیمر و لاستیک

آزمایشگاه تخصصی پلیمر و لاستیک طاها قالب با هدف کنترل پارامترهای کیفیت و همچنین گسترش تنوع محصولات پلیمری در صنایع نفت، گاز و پتروشیمی تاسیس شده است. این آزمایشگاه با بهرهگیری از اعضای هیئت علمی، مهندسان متخصص و دستگاههای پیشرفته آزمایش بر اساس استانداردهای ملی و بینالمللی، از جمله کاربردیترین آزمونهای صنایع پلیمر و لاستیک، موفق به دریافت گواهینامه ISO 17025 شده است. این آزمایشگاه دارای تجهیزات ویژهای برای تعیین عمر واشرهای مبدل حرارتی صفحهای به منظور افزایش طول عمر آنها است.

آزمایشگاه متالوگرافی و تستهای غیرمخرب

آزمایشگاه متالوگرافی و تستهای غیرمخرب

انواع مختلف فرآیندهای تولید مانند ماشینکاری، جوشکاری و روکشکاری، نیازمند متالوگرافی و بررسی میکروسکوپی برای دستیابی به خواص مطلوب آلیاژها و فلزات مانند چقرمگی، سختی و استحکام کششی هستند. برای اطمینان از کیفیت قطعات تولید شده، تستهای غیرمخرب اجتنابناپذیر است. به همین منظور، آزمایشگاه متالوگرافی و تستهای غیرمخرب (NDT) تجهیز شده و میتواند خدمات مختلف متالوگرافی و تستهای غیرمخرب را ارائه دهد. این آزمایشگاه نیز به دلیل تخصص و تجهیزات تخصصی خود، گواهینامه ISO 17025 را دریافت کرده است.

راه حلهای نرمافزاری

TIP ® Taha Intelligence Platform

نظارت و تحلیل لحظهای فرآیند مبدلهای حرارتی صفحهای (PHEs)

®TGT SheetCut

برش بهینه ورق برای کمترین ضایعات

® TGT ProjectTrack

مدیریت جامع پروژه و ردیابی اسناد

® TGT DocAuto

مستندسازی خودکار برای افزایش بهرهوری

®TGT PHE-Design Software

طراحی سفارشی مبدل حرارتی صفحهای برای عملکرد بهینه

®Taha - SEP

شبیهسازی جریان پیشرفته برای میست الیمینیتورها

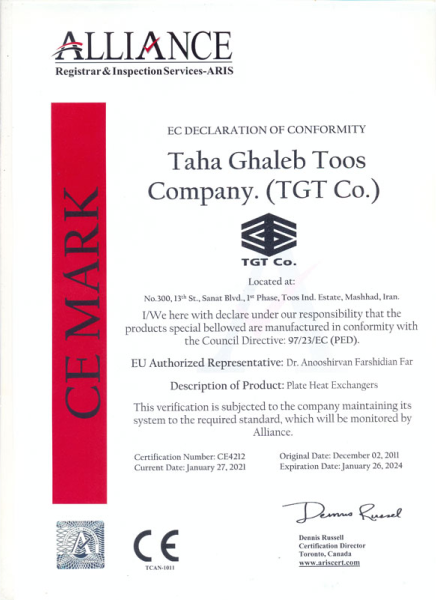

استانداردها و گواهینامهها

ISO 45001

ISO 9001

ISO 14001

CE4212

پایداری

نوآوری برای فردایی سبزتر

طاها قالب در خط مقدم توسعه راه حلهای نوآورانه برای مقابله با چالشهای زیستمحیطی جهانی قرار دارد. با بهرهگیری از فناوریهای پیشرفته و مواد پایدار، ما قادر به تولید محصولاتی هستیم که هم کارآمد و هم سازگار با محیط زیست هستند. تعهد ما به تحقیق و توسعه تضمین میکند که ما به طور مداوم در حال بررسی روشهای جدیدی برای کاهش ردپای کربن خود و ترویج پایداری هستیم.

مغزهای متفکر پشت صحنه

دکتر انوشیروان فرشیدیانفر

مدیرعامل

هیئت علمی مهندسی مکانیک دانشگاه فردوسی مشهد

کوروش فرشیدیانفر

مدیر ارشد بازاریابی (CMO)

عضو هیئت مدیره

علیرضا قاسمی

رئیس هیئت مدیره (COB)

مدیر ارشد مالی (CFO)

حسین خطیبی

مدیر ارشد عملیات (COO)

عضو هیئت مدیره

دکتر علیرضا فرشیدیانفر

مدیر ارشد تولید

عضو هیئت مدیره

دکتر اردشیر فرشیدیانفر (1962-2020)

دکتر فرشیدیانفر از سال 2000 تا 2020 بنیانگذار، عضو هیئت مدیره و مدیر ارشد فناوری (CTO) شرکت طاها فالب بود. او در ایران پیشگام طراحی و ساخت مبدلهای حرارتی صفحهای شد. در سال 2013 به عنوان کارآفرین و مهندس سال انتخاب شد. نتایج کارهای روشنگرانه دکتر فرشیدیانفر در 14 کتاب، مقالات متعدد مجلات و مجموعه مقالات کنفرانس منتشر شده است.