Taha Disk®

Taha Disk®

Plate Heat Exchanger (PHEs)

Function

How It Works

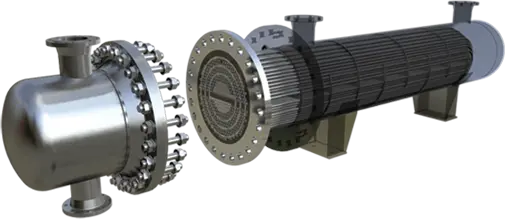

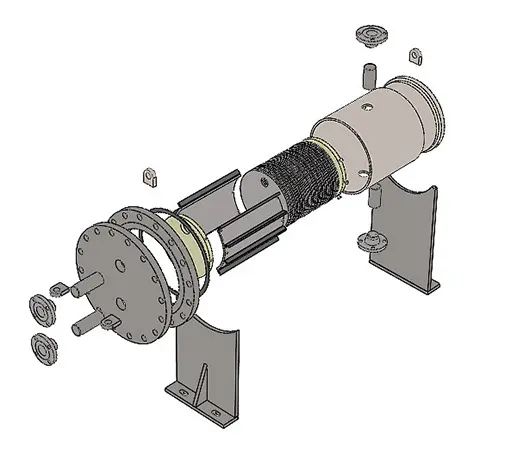

Taha-Disk® heat exchangers combine the best features of both gasket plate and shell-and-tube heat exchangers. They offer the highest operating pressures and temperatures, and the highest efficiency among all heat exchanger types. The fully-welded construction, using laser welding, ensures high reliability and minimal leakage, even at extremely low or high temperatures and pressures.

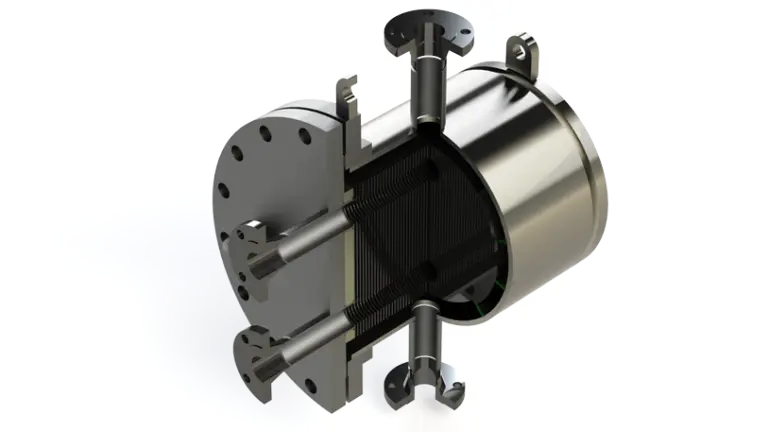

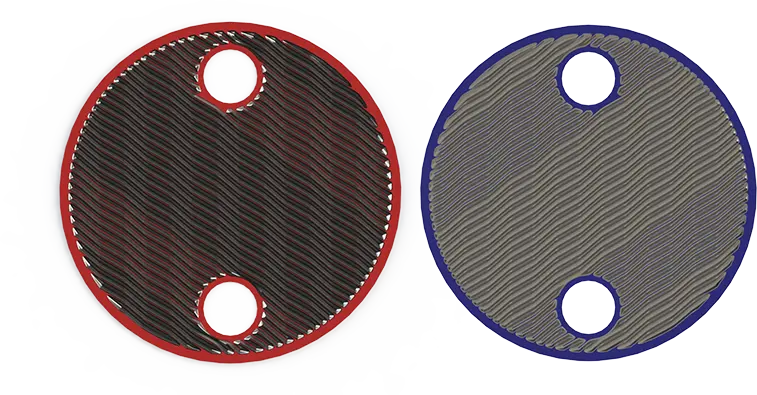

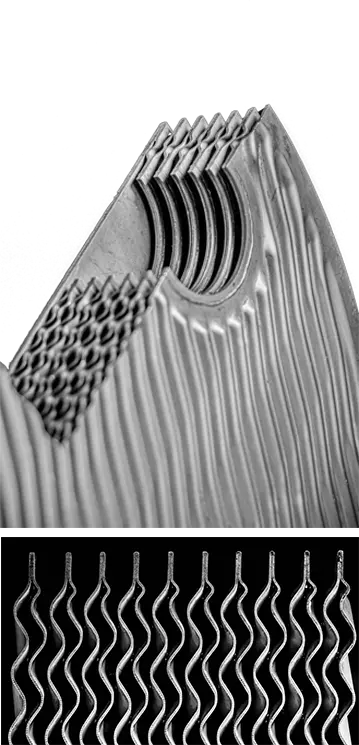

In a Taha-Disk® exchanger, the corrugated circular plates are divided into two halves, with inlet and outlet ports for fluid flow. The cold fluid enters the exchanger and is distributed through the narrow spaces between the plates. The hot fluid enters the shell and flows through the remaining space, transferring heat to the cold fluid. This design provides flexibility for various piping systems and enhances overall exchanger efficiency.

Specifications

Materials and Construction

Taha-Disk® exchangers are constructed using high-quality materials, including:

- Plates: AISI 304L, AISI 316L, Alloy 904L, Alloy 254 SMO, Nickel 201/200, Hastelloy C-276, Hastelloy C-2000, Hastelloy HYBRID-BC1

- Shell: AISI 304L, AISI 316L, Alloy 904L, Alloy 254 SMO, Nickel 201/200, Hastelloy C-276, Hastelloy C-2000, Hastelloy HYBRID-BC1

Product features

Design and Innovation

TGT has optimized the design of Taha-Disk® exchangers through extensive simulations. The unique corrugated plate geometry maximizes heat transfer and minimizes pressure drop. Key features include:

- Laser cutting: Precision cutting of plates for optimal fit and performance.

- Hydraulic forming: Shaping plates using high-pressure hydraulic presses.

- Customized designs: Tailored solutions to meet specific customer requirements.

Competitive Advantages

TGT Competitive Edge

TGT’s Taha-Disk® heat exchangers offer superior performance and reliability compared to traditional heat exchangers. Key advantages include:

- High heat transfer efficiency: Optimized plate design and construction.

- Compact size: Smaller footprint compared to shell-and-tube exchangers.

- Fully-welded construction: Eliminates gaskets and reduces the risk of leaks.

- Low fouling rates: Improved fluid flow and reduced deposition.

- Flexibility: Can handle a wide range of fluids and operating conditions.

- Ease of cleaning: Accessible design for thorough cleaning.

TGT’s commitment to innovation and quality has resulted in a product that is well-suited for demanding applications in industries such as:

- Chemical processing

- Shipbuilding

- Oil and gas

- Petrochemical

- HVAC

- Steam heating

By leveraging advanced manufacturing techniques and materials, TGT’s Taha-Disk® heat exchangers provide reliable and efficient heat transfer solutions.

Additional Notes:

- The Taha-Disk® design offers flexibility in flow patterns (counter-current, parallel, cross-flow) to suit various process requirements.

- The fully-welded construction ensures a long service life and minimal maintenance.

- TGT’s expertise in heat exchanger design and manufacturing enables them to provide customized solutions for complex applications.