Options

Explore HTS

Options

HTS Accessories

HTS Spare parts

Explore separation

Options

separation Accessories

separation Spare parts

Explore Rotary Equipment

Options

Rotary Equipment Accessories

Rotary Equipment Spare parts

Explore Pelletizing

Options

Pelletizing Accessories

Pelletizing Spare parts

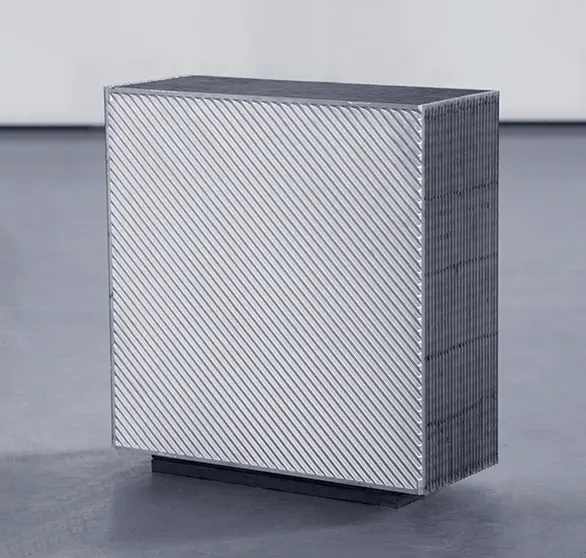

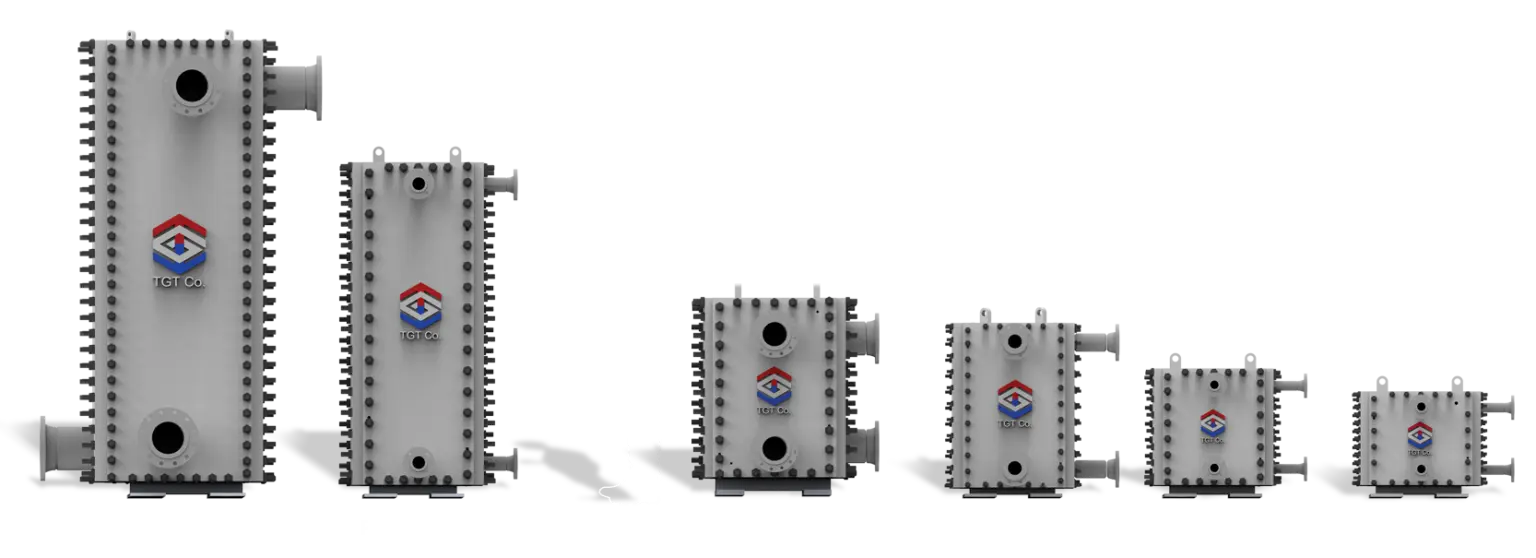

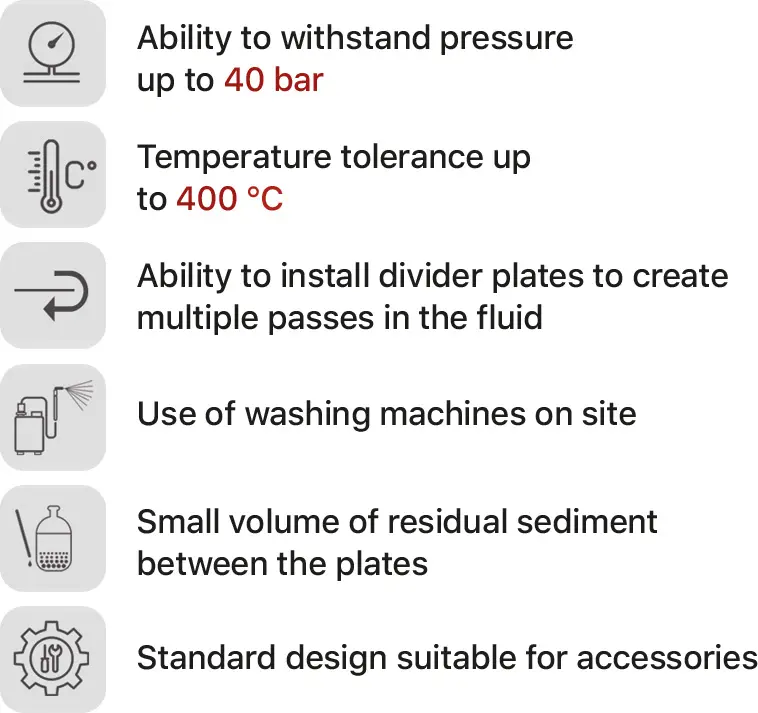

The Taha-Bloc® fully welded plate heat exchanger offers an ideal solution for heat transfer involving corrosive fluids. Completely sealed by laser welding, these exchangers can operate at higher temperatures and pressures compared to gasket-sealed models. This is due to features such as thick and tall panels, laser-welded plate seals, and bolted body connections.

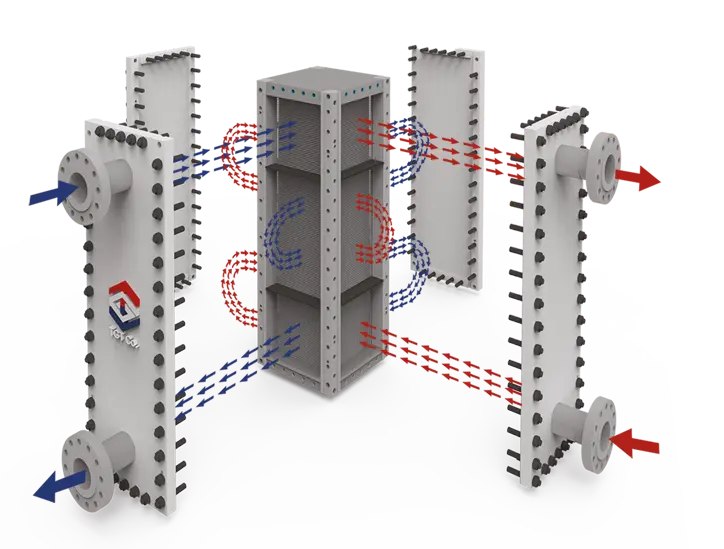

Fluid distribution within Taha-Bloc® exchangers is achieved through a series of welded plates forming the exchanger’s core. Both hot and cold fluids flow perpendicularly between these plates, and side plates are used to create multiple passes for enhanced thermal efficiency.

The plates in Taha-Bloc® heat exchangers are typically made from materials such as : AISI 304L, AISI 316L, Alloy 904L, Alloy 254 SMO, Nickel 201/200, Hastelloy C-276, Hastelloy C-2000, and Hastelloy HYBRID-BC1. The choice of material depends on the specific application and the nature of the fluids being processed.

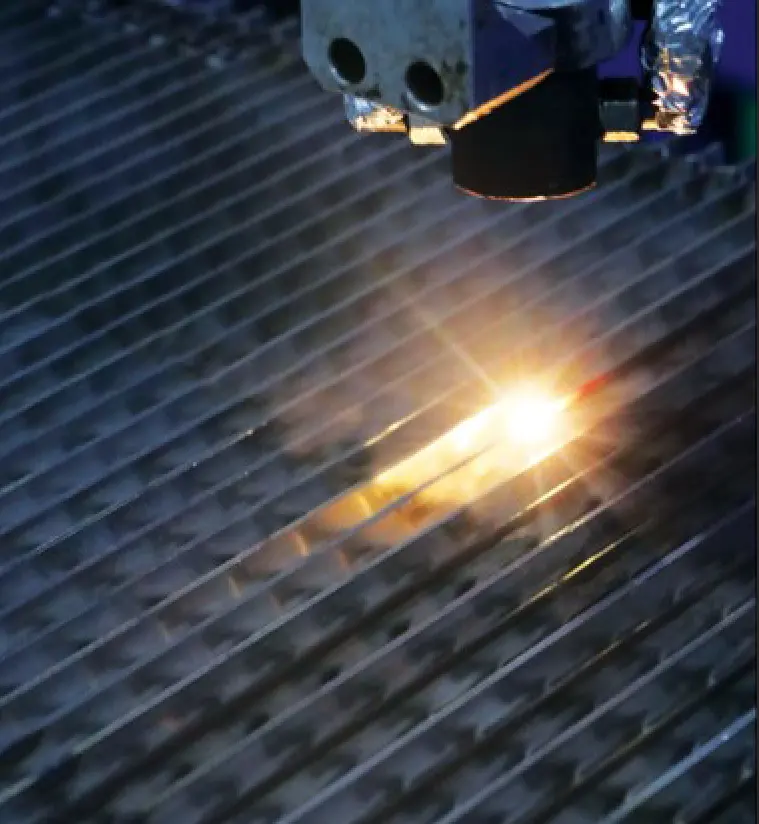

The Taha-Bloc® plate heat exchanger can operate at higher temperatures and pressures than conventional gasket-sealed plate heat exchangers due to features such as thick and tall panels, laser-welded plate seals, and bolted body connections. The plates are joined and sealed using advanced laser welding technology at TGT’s state-of-the-art laser center in the region.

As industries such as petrochemicals and power generation face increasing demands for heat transfer equipment that can withstand high temperatures and pressures, TGT’s Taha-Bloc® fully welded plate heat exchanger offers a superior solution. The laser welding process ensures a high-quality, leak-free seal, and the use of advanced materials allows for operation in harsh environments. TGT’s Taha-Bloc® exchangers also offer advantages such as : -energy efficiency -optimized design -compact dimensions. These features, combined with TGT’s expertise in heat exchanger design and manufacturing, make Taha-Bloc® exchangers a leading choice for demanding applications.