Separation Systems

Get to know mist eliminators

What is mist eliminator ?

Industrial mist eliminators are one of the most important separation equipment …

What is mist eliminator ?

Industrial mist eliminators are one of the most important separation equipment in industrial processes that are used to separate liquid and solid particles from the gas streams. The basis of the work of mist eliminators is by changing the direction of the gas flow and due to the effects of inertia or movement of particles the water particles will be separated from the main gas stream. In the case of particles larger than 10 microns in size, due to the heavy weight of these droplets, they tend to resist the change in the direction of the gas flow, which causes these particles to collide with the plates and walls and eventually accumulate and leave the system due to gravity.

TGT solution for customer mists in process

Separation group offers a wide range of solutions for your product such …

TGT solution for customer mists in process

Separation group offers a wide range of solutions for your product such as vane type, mesh type and cyclone type mist eliminator. By using inertia difference between mist particles each one of these types are suitable for specific application based on particle size.

TGT step-ups among others

Due to the industrial position of TGT company, wide range of business …

TGT step-ups among others

Due to the industrial position of TGT company and the complexity of mist eliminators, wide range of business partners are gathered under one brand for manufacturing these separators. Our custom-made software has provided us a clear vision through customer problems and solutions for achieving maximum efficiency. At last, since mist eliminators also come with vessels TGT company could also take care of the vessel manufacturing process.

Explore and compare

Vane type

Series of parallel corrugated plates manufactured from stainless steel, Thermal-Set Plastics and Fiber-Reinforced Plastic (FRP) materials.

Even due this type of separators is mostly common among steel manufacturing complexes there are less efficient in removing small droplets than other types.

Removable particle size above

10μm

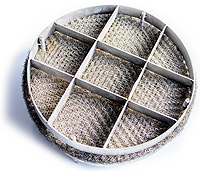

Mesh type

A stream of steam or gas containing liquid droplets passes through the pads. Materials used are usually stainless steel and polymers.

Particles with high momentum deviate from the gas streamline and hit the fiber. Steam and gas pass freely through the meshes.

Removable particle size less

10μm

Cyclone type

This type is usually coming in a form of a hollow vessel with special inlet pipe that causes rotation in the gas flowing in and creating vortex.

Creating a vortex and separating waste solid or liquid particles from the gas flow with the particle inertia.

Removable particle size above

50μm

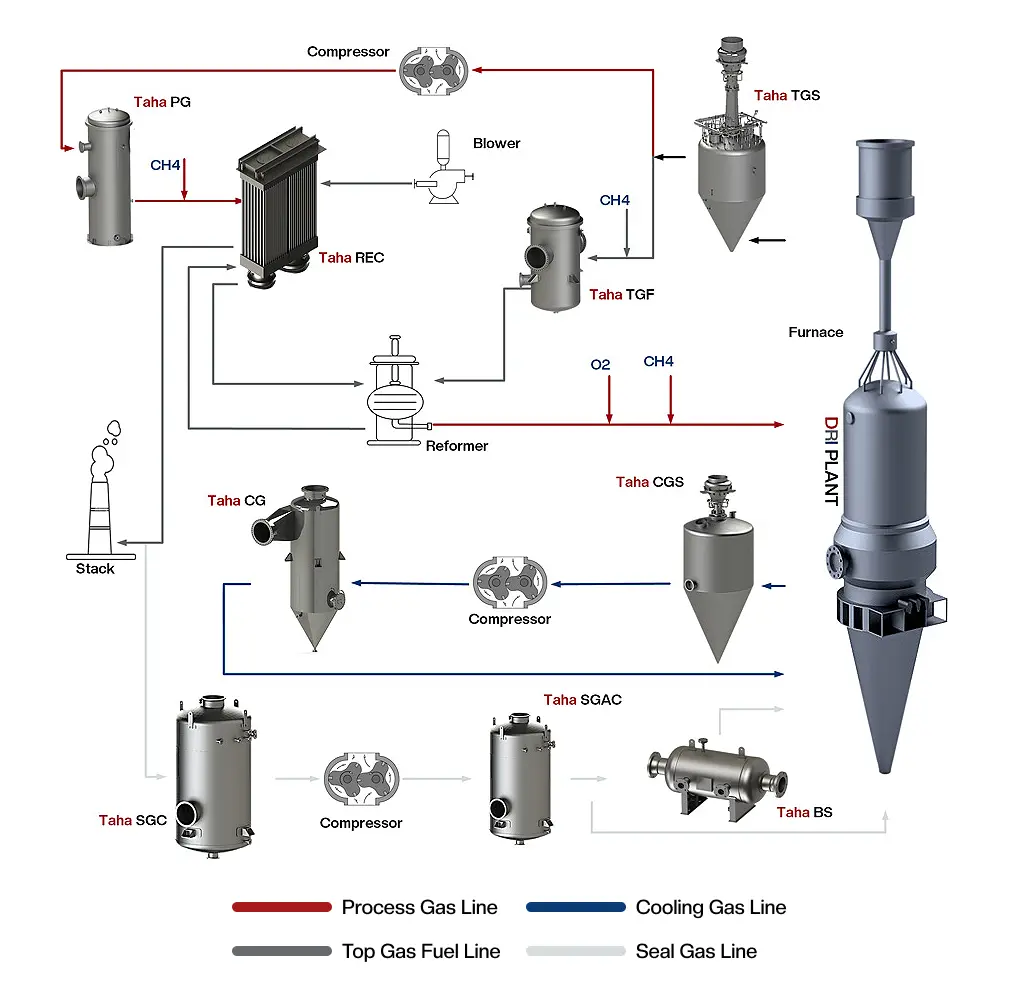

Taha TGS (Top Gas Scrubber)

Taha TGF (Top Gas Fuel) Demister

Taha PG (Process Gas) Demister

Taha REC (Recuperator bundle)

Taha CGS (Cooling Gas Scrubber)

Taha CG (Cooling Gas) Demister

Taha BS (Bottom Seal) Demister

Taha SGC (Seal Gas Cooler)

Taha SGAC (Seal Gas After Cooler)

Why TGT separations

Customized design by the engineering department at TGT.

The exclusive and custom design of industrial mist eliminators tailored to the needs of the customer is carried out by the engineering department. Based on the process information, including temperature, pressure, maximum working flow, allowable pressure drops, the ratio of gas to liquid present in the process and the required separation efficiency, the design and sizing are carried out. Our mist eliminator designs are based on CFD simulation, experimental validation, and well-known standards in the industry to achieve an optimal design on efficiency and pressure drop. All designs are based on industry standards (including API, ASME, IPS, and GPSA).

Complete in-house production cycle

TGT stands as the sole company in Iran that encompasses the entire production cycle of cutting rotor from scratch to customer delivery within a single facility

Innovative optimized product and solutions

A mist eliminator designed with the Taha-SEP software, a specialized tool developed by TGT engineers for optimized design and sizing of two-phase separation systems.