Semi Welded PHE

Semi Welded PHE

Plate Heat Exchanger (PHEs)

Function

How It Works

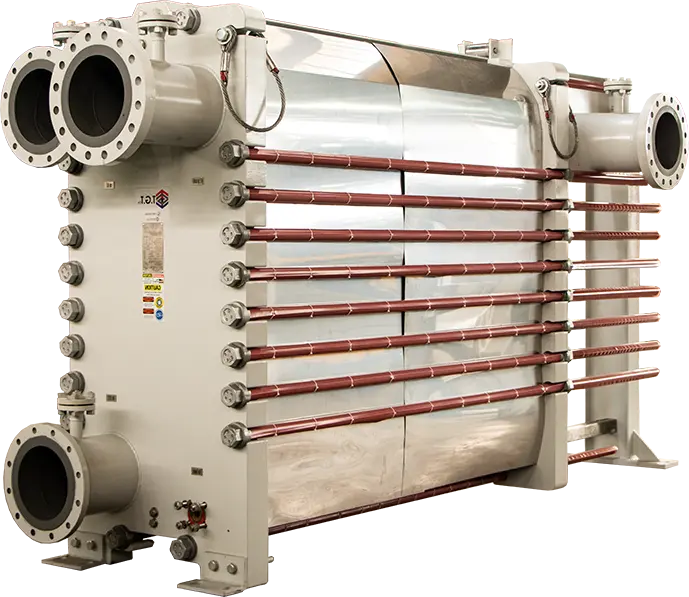

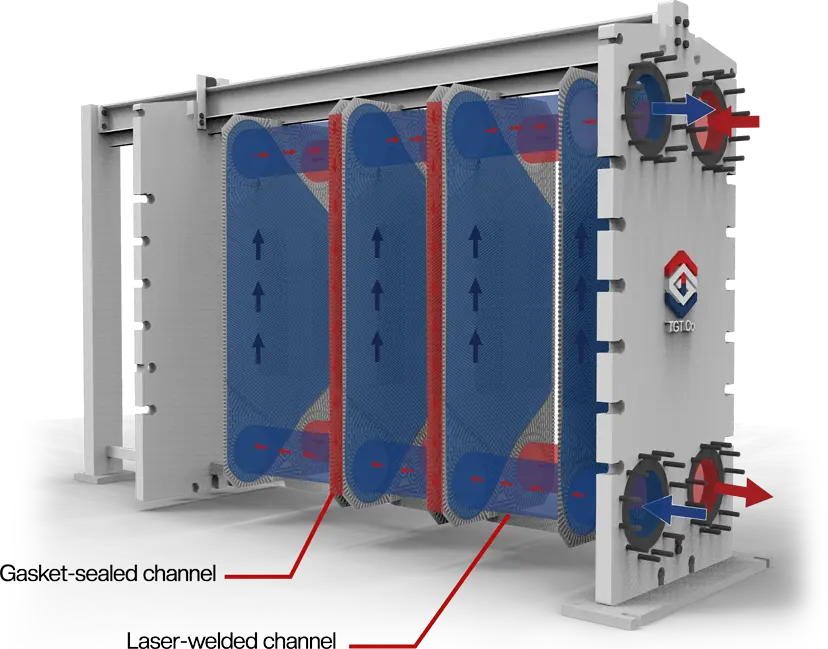

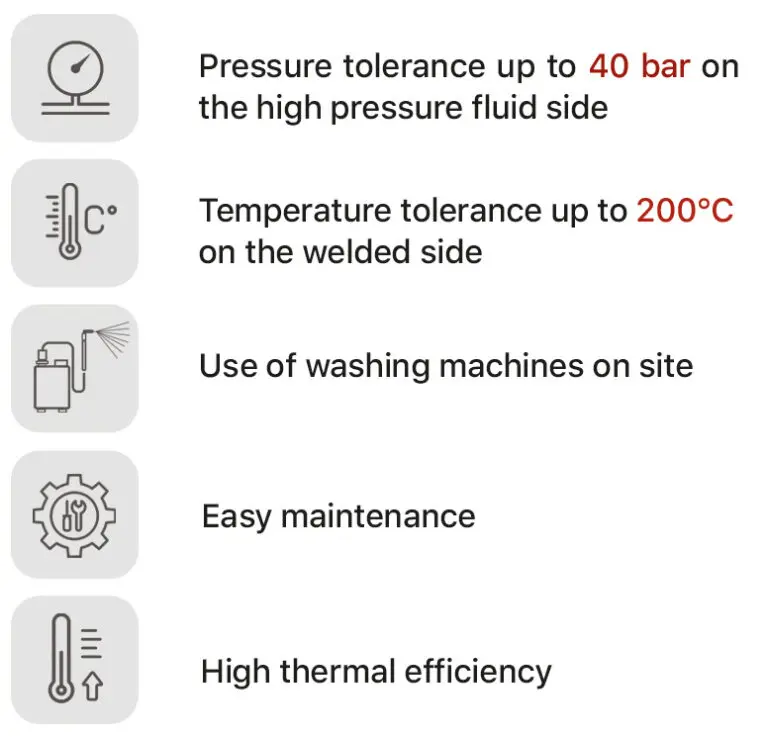

Semi-welded plate heat exchangers (SWPHEs) are optimized for high-pressure applications where traditional gasket plate exchangers are unsuitable. They offer a robust solution for processes involving high-pressure fluids or those that are incompatible with gaskets. SWPHEs consist of corrugated metal plates that are partially welded together, creating a leak-tight seal. The fluids flow through alternating channels within the plates, transferring heat efficiently.

TGT’s Taha-Evap® and Taha-Condense® are specialized SWPHEs designed for evaporators and condensers, respectively. These exchangers offer rapid startup and shutdown capabilities, adjustable heat transfer area, and low operating costs.

Specifications

Materials and Construction

SWPHE plates are typically made of corrosion-resistant metals such as:

- Stainless steel (AISI 304L, AISI 316L, 904L, 254 SMO)

- Nickel alloys (Hastelloy C-276, Nickel 200/201)

- Titanium and its alloys (Grade 1, Grade 11, Titanium-Palladium)

The choice of material depends on the specific application and the properties of the fluids being processed.

Product features

Design and Innovation

TGT utilizes advanced laser welding technology to create strong, durable bonds between the plates in its SWPHEs. This process is carried out in a state-of-the-art laser facility, ensuring precise and consistent welds. TGT’s engineering team has optimized the design of SWPHEs to maximize thermal efficiency and minimize pressure drop.

Competitive Advantages

TGT Competitive Edge

TGT offers several competitive advantages in the SWPHE market:

- Advanced manufacturing: TGT employs state-of-the-art laser welding technology to produce high-quality SWPHEs.

- Customized designs: TGT can tailor SWPHEs to meet specific customer requirements.

- High-pressure capability: SWPHEs are designed to handle high-pressure applications.

- Corrosion resistance: A wide range of materials is available to ensure compatibility with corrosive fluids.

- Efficient heat transfer: The corrugated plate design and optimized flow channels maximize heat transfer.

- Low maintenance: The all-welded construction reduces the risk of leaks and simplifies maintenance.

TGT’s Taha-Evap® and Taha-Condense® offer additional benefits, including:

- Rapid startup and shutdown: Ideal for processes requiring quick response times.

- Adjustable heat transfer area: Enables flexible operation.

- Low operating costs: Optimized design and efficient operation.