Recuperators

Recuperator

Air-to-air heat exchangers

Function

How It Works

Recuperators are air-to-air heat exchangers that recover heat from process exhaust gases and utilize it to preheat incoming gases. These exchangers are typically constructed with finned surfaces. TGT has developed a new generation of plate-type recuperators, employing specially designed chevron-shaped plates for enhanced heat transfer. Compared to finned recuperators, TGT’s plate-type models offer a 30% higher heat transfer rate and reduced weight.

Specifications

Materials and Construction

A cyclone is essentially a vessel with a specific geometry designed to separate fluid phases. The commonly used materials for the vessel are carbon steels such as A516 Gr. 70. The manufacturing process involves rolling, dished head forming, and welding.

Key advantages of recuperators include

- Energy Recovery: These exchangers recover energy from exhaust gases, reducing overall energy consumption.

- Lower Operating Costs: By reducing the need for additional heating or cooling, operating costs are significantly decreased.

- Simple Installation and Operation: Recuperators are relatively easy to install and operate.

- No Cross-Contamination: As the two air streams are completely separated, there is no risk of contamination or direct material exchange.

- High Efficiency: Especially effective when there is a significant temperature difference between the two streams.

Applications

- Automotive

- Food processing

- Chemical, petrochemical, and steel

- Industrial systems (oil and gas)

- Sports arenas and large buildings

- HVAC systems

Types of Recuperators

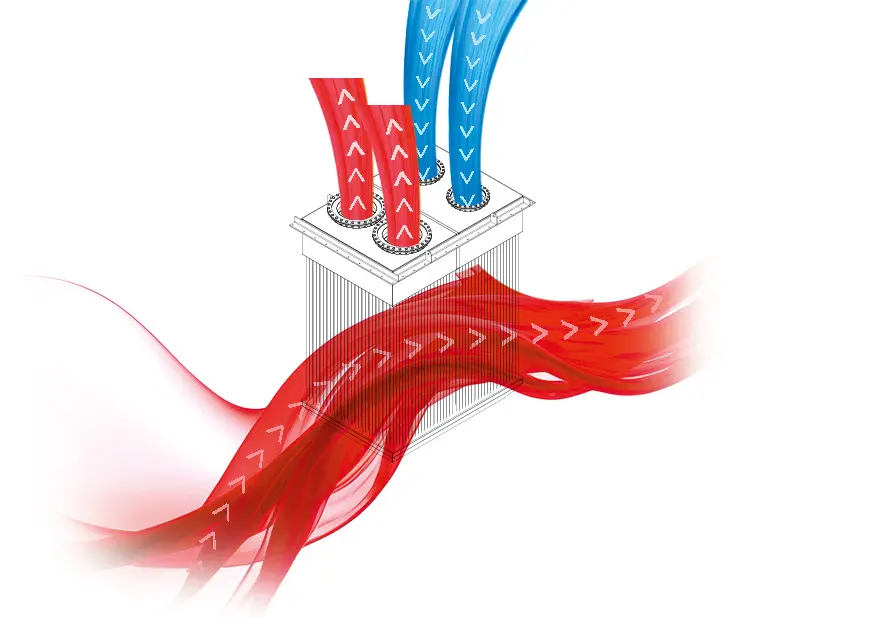

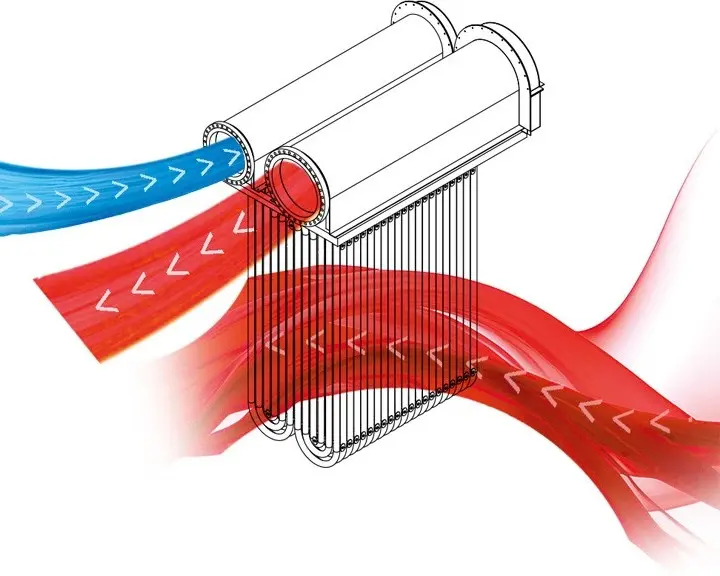

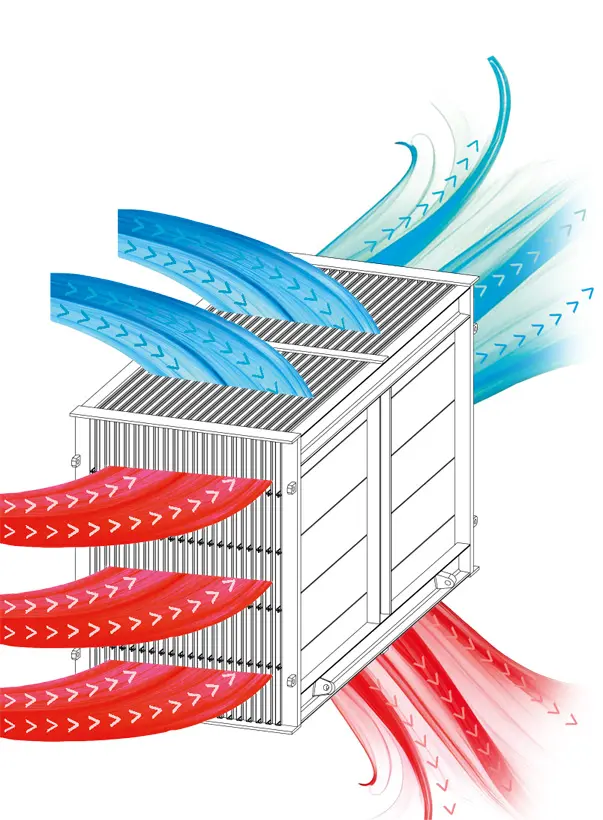

Cross-Flow: In this configuration, hot air enters the plates and exchanges heat with cold air entering from a perpendicular direction.

Counter-Flow: Here, hot and cold air flow in opposite directions through the plates.

Cross-Counter Flow: This type combines elements of both cross-flow and counter-flow configurations.

Specifications

Materials and Construction

Recuperator plates can be made from various materials, including:

- Carbon Steel

- AISI 304L

- AISI 304

- AISI 304H

- AISI 321

- AISI 321H

- AISI 316

- AISI 316L

- AISI 316H

- Type 316Ti

- AISI 310S

- AISI 310H

- AISI 309S

- AISI 309H

Product features

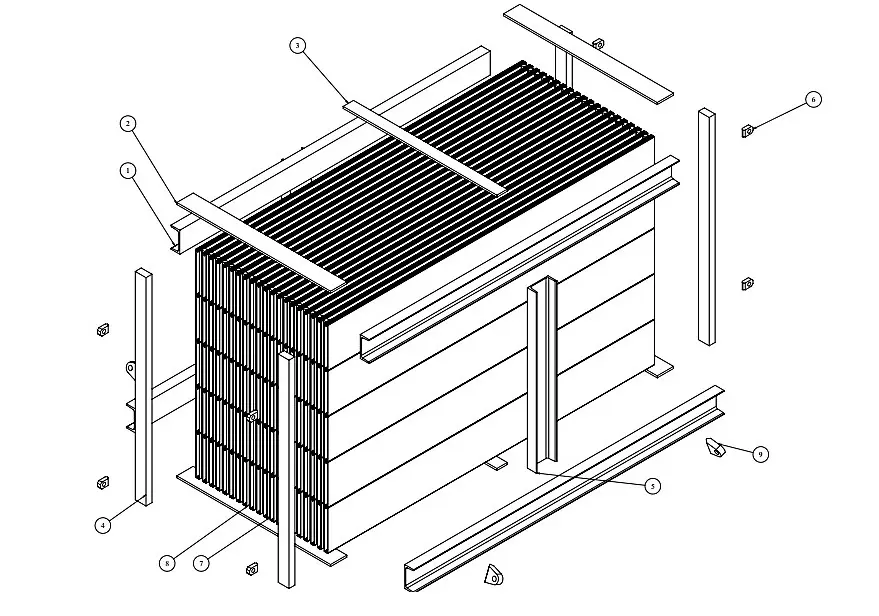

Design and Innovation

TGT has optimized the geometry of its fully welded recuperators through extensive simulations. The unique chevron pattern employed in the plates represents a significant advancement in recuperator design. Other key features include:

- Exclusive use of laser cutting and welding processes

- Formation of heat transfer plates using the largest hydraulic press in the Middle East, manufactured by TGT.

Competitive Advantages

TGT Competitive Edge

TGT’s recuperators offer significant advantages in various industries, such as steel, cement, and petrochemicals. The specially designed chevron-shaped plates in TGT’s petrochemical recuperators provide a 30% higher heat transfer rate compared to finned models, along with lower weight, pressure drop, and fouling. In the steel industry, TGT recuperators are used to preheat combustion air for direct iron reduction processes, resulting in significant energy savings and reduced production costs. These recuperators are designed to withstand harsh operating conditions and high temperatures, ensuring long service life and minimal maintenance. TGT’s air-to-air heat exchangers also offer simultaneous energy and water optimization. By condensing moisture from the hot air stream, these systems can generate usable water, making them particularly beneficial for industries facing water scarcity.