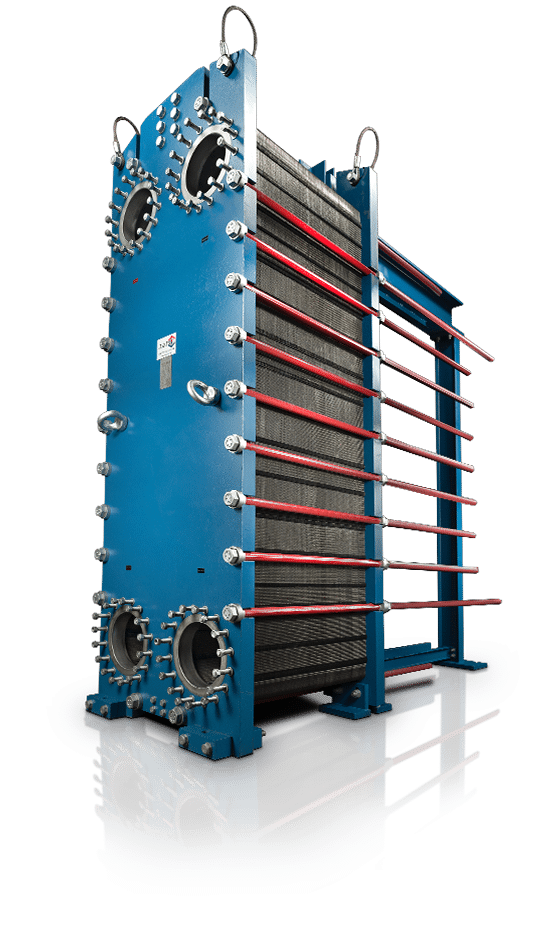

Gasketed PHE

Taha Disk®

Taha Bloc®

Semi-Welded-PHE

Brazed PHE

PHE Accessories

PHE Spare Parts

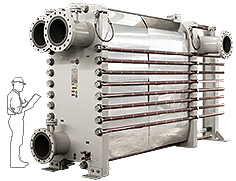

Plate Heat Exchangers

Get to know Plate Heat Exchangers (PHE)

What is a PHE

A plate heat exchanger is a device used to transfer heat between two …

PHE advantages

PHEs have several advantages. They are very efficient at transferring heat, meaning they can …

PHE advantages

PHEs have several advantages. They are very efficient at transferring heat, meaning in compare of other conventional heat exchangers heat transfer occurs much faster with consumption of less material. When they require less material to manufacture, they also occupy less space in the same environment as conventional heat exchangers.

PHE applications

PHEs are used in many industries. They can be found in food processing, chemical processing, ….

PHEs classification and comparisons

Gasketed

Plates are squeezed to each other with gasket between them for sealing.

Convenient solution with numerous size and models with minimum maintenance.

Max design temp

200°C

Max design pressure

25bar

Semi welded

Plates are Welded together by pair and each pair are squeezed together with a gasket.

Suitable for fluids that have corrosion effect on polymer gaskets.

Max design temp

200°C

Max design pressure

40bar

Taha-Bloc®

Withstand higher pressure and temperature in compare of other PHEs.

By replacing gaskets with welded plates corrosion and low pressure and temperature limitations will be lifted.

Max design temp

600°C

Max design pressure

50bar

Taha-Disk®

Withstand higher pressure and temperature in compare of Taha-Bloc.

By having circular plates, the stress caused by the fluid’s pressure will not be concentrated, and higher-pressure applications will be possible.

Max design temp

600°C

Max design pressure

50bar

Brazed

Plates are brazed together by using a vacuum furnace.

Eliminates the need of gaskets and heavy frames compared to gasket plate heat exchangers.

Max design temp

400°C

Max design pressure

30bar

Why TGT is the best place

for your PHE solutions

Fast response and delivery time

One of the main advantages of fully domestic production of TGT company's products is the accuracy and flaw less control over production line. With the means of automation and humane resources the fastest production record in Middle East is achieved.

Complete in-house production cycle

TGT stands as the sole company in Iran that encompasses the entire production cycle of plate heat exchangers from start to customer delivery within a single facility.

Innovative optimized product and solutions

TGT Company, based on the indigenous knowledge developed within the company, has been able to develop a specialized software for designing various types of PHEs for the first time in the Middle East, placing it alongside the world's pioneers in this field.

On-call 24/7 support and service

In response to the critical needs of industries, TGT has established the Middle East's largest specialized center for heat exchanger exchanger support, maintenance, and repair.

PHEs are used in many industries. Any industry that possesses hot and cold streams can benefit from using plate heat exchangers. For example, they are used to heat or cool milk in dairy processing, to heat and cool oil in refineries, and to heat or cool water in buildings.

PHEs are used in many industries. Any industry that possesses hot and cold streams can benefit from using plate heat exchangers. For example, they are used to heat or cool milk in dairy processing, to heat and cool oil in refineries, and to heat or cool water in buildings.