Pinion

Pinion

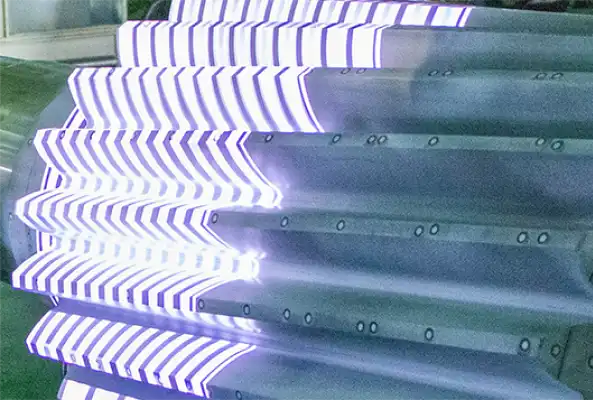

Grinding Mill Pinons

Function

How It Works and operation

Grinding mill pinions are essential components for the efficient operation of grinding mills. These pinions are responsible for transmitting power to the grinding mill, allowing for the grinding of raw materials such as ores and minerals. By engaging with the gear system, they facilitate the rotation of the grinding mill, which is necessary for the reduction of material size. The design of grinding mill pinions ensures they can withstand high torque while maintaining structural integrity under extreme conditions. Manufactured to AGMA standards, these pinions are engineered to deliver optimal performance in high-load applications.

Specifications

Materials and Construction

Grinding mill pinions are produced from high-quality materials, typically high-strength alloy steels, designed to meet AGMA standards. These materials are chosen for their durability, toughness, and wear resistance, ensuring the pinions can endure the demanding conditions of grinding mills. The maximum design power for these pinions is 5 MW, and the maximum module is 42mm, which ensures they can handle the high torque demands of the grinding process. The pinions are designed for efficient and reliable performance over a long service life.

Product features

Design and Innovation

The design of the grinding mill pinions emphasizes both durability and precision. TGT’s advanced manufacturing processes and the use of state-of-the-art machinery ensure high-quality production, with tight tolerances for the gear profiles. The pinions are crafted to provide precise and consistent power transmission, ensuring the grinding mill operates smoothly and efficiently. TGT’s expertise in advanced machining techniques, including CNC milling and advanced jig and fixture designs, enables the production of pinions that meet the highest standards in the industry. This precision guarantees the longevity and optimal performance of the pinions, even under the most demanding operational conditions.

Competitive Advantages

Design and Innovation

TGT’s grinding mill pinions offer significant advantages over conventional products. The use of high-quality materials and advanced machining techniques ensures that these pinions exhibit superior durability, high wear resistance, and excellent performance under high-torque conditions. The high precision of TGT’s pinions minimizes inefficiencies and reduces the risk of mechanical failure, providing a cost-effective solution for grinding mills. Additionally, the design ensures minimal maintenance requirements and extends the service life of the grinding mill equipment. These competitive advantages make TGT’s grinding mill pinions an ideal choice for industries that rely on reliable and efficient grinding mill operations.