PHE Accessories

Accessories

For plate heat exchangers

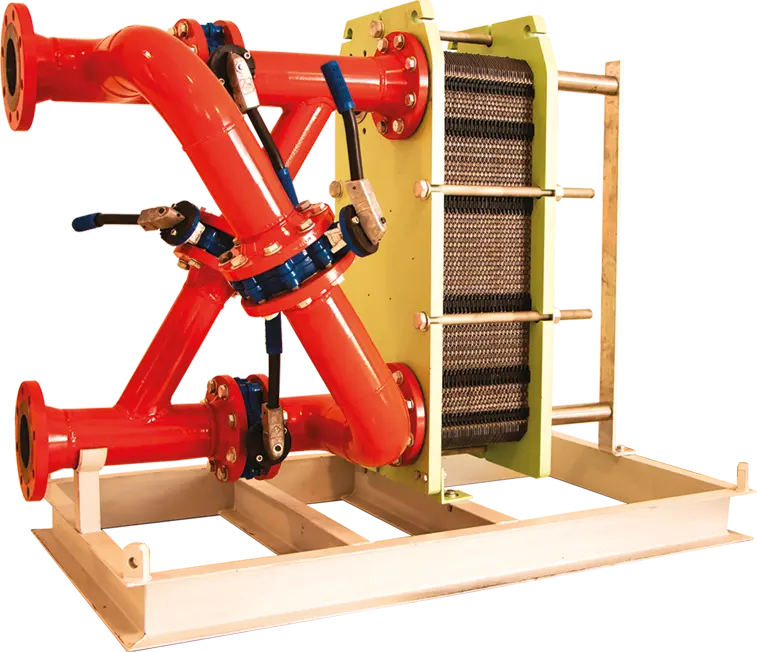

Oil cooler skid

Integrated Piping and Controls

Many industries face challenges in integrating heat exchangers into their production lines due to piping limitations. To address this issue, TGT has developed a comprehensive solution: full packaged PHEs with integrated piping, temperature and pressure gauges, and control valves. These pre-assembled units are mounted on a single frame, minimizing installation space and maintenance requirements. Primarily used as oil coolers in power plants, these complete packages also find applications in petrochemical and industrial facilities.

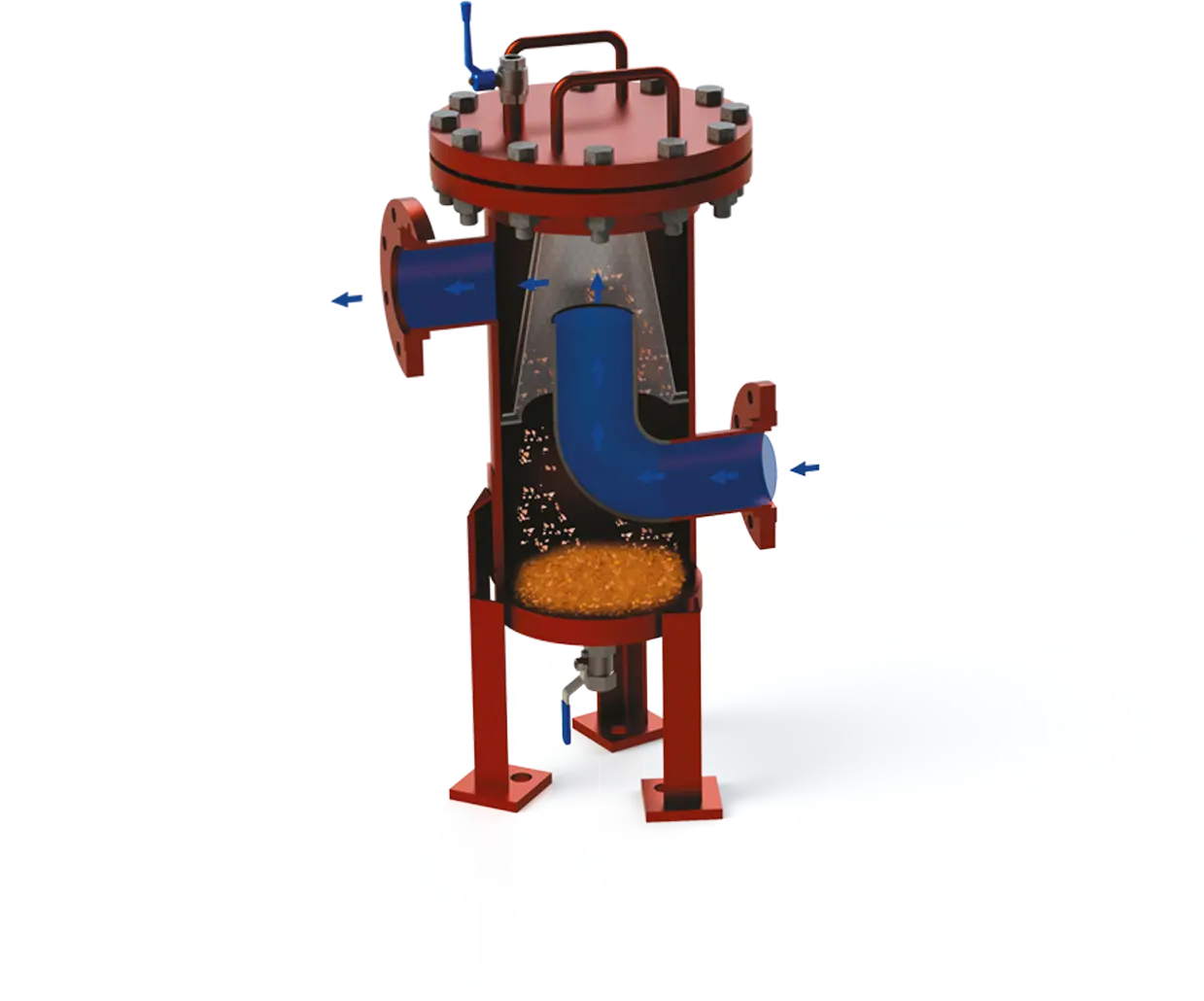

Strainer

Advanced Filtration Solutions

Taha strainer is used in a wide range of industries to separate particles from water and other liquids. The shape and size of the conical plate of Taha strainer makes it more optimal than the normal basket strainers and reduces the operating costs of the system. When water enters the strainer body from the bottom and flows upwards, the collected particles are pushed out of the discharge port under pressure without interrupting the downstream flow. The type of screen inside the strainer can be selected according to the customer’s needs. There are a variety of options, from large mesh sheets to fine mesh metal netting.

Cleaning-in-place unit

Optimal Heat Exchanger Performance

The presence of impurities and deposits in fluids can significantly reduce the efficiency of heat exchangers. Over time, this can lead to clogging of heat transfer channels and equipment failure. Proper and periodic cleaning of the equipment using acid cleaning systems with a specific concentration of specialized acids can effectively address this issue without damaging the exchanger plates. A key advantage of the acid cleaning process is that it eliminates the need for disassembly of the exchanger by customers or TGT service technicians. Acid cleaning of heat exchangers is a preventive measure to avoid line shutdowns and permanent equipment damage, leading to significant reductions in operating and maintenance costs. Leveraging its 30 years of expertise in heat transfer and heat exchanger maintenance, TGT has designed and manufactured on-site acid cleaning systems. These systems can be customized to various sizes, flow rates, and specific performance requirements. The acid cleaning process for different heat exchangers must be carried out at a specified design temperature and using appropriate chemical solutions tailored to the materials used in the exchangers. TGT’s experienced engineers have developed comprehensive cleaning process guidelines for clients and provide on-site acid cleaning systems to facilitate timely and effective cleaning of heat exchangers.

Chlorine-free adhesives

Protecting Heat Exchangers from Corrosion

A major issue with using non-standard, chlorine-containing adhesives in equipment like heat exchangers is the presence of elements in their formulation that cause stress-cracking and severe localized corrosion on stainless steel plates. The presence of chlorine in the structure of these adhesives, especially at high temperatures, leads to corrosion at the gasket grooves. TGT , a knowledge-based company, has developed a range of adhesives free from harmful elements like chlorine, which do not cause corrosion in heat exchangers. These adhesives are suitable for various industries, including oil, gas, petrochemical, mining, and power generation.

Hydrolic Wrench

Automated Disassembly

In production lines utilizing plate heat exchangers, downtime is a critical concern. TGT has addressed this challenge by designing innovative and practical auxiliary equipment, including advanced hydraulic systems specifically engineered for heat exchanger assembly and disassembly. TGT’s hydraulic wrenches employ compact hydraulic jacks to automatically open and close the bolts of gasket-type and semi-welded heat exchangers. These portable systems eliminate the need for high-torque pneumatic wrenches and excessive manpower, enabling effortless disassembly of plate heat exchanger plates for cleaning or replacement.

Backflush system

Reverse Flow Cleaning

Backflush systems remove fluids where the internal flow is viscous and dirty when the internal plates and channels are blocked. These particles are removed by reversing the flow direction. Blocked heat exchangers will be cleaned without disassembling the plates.

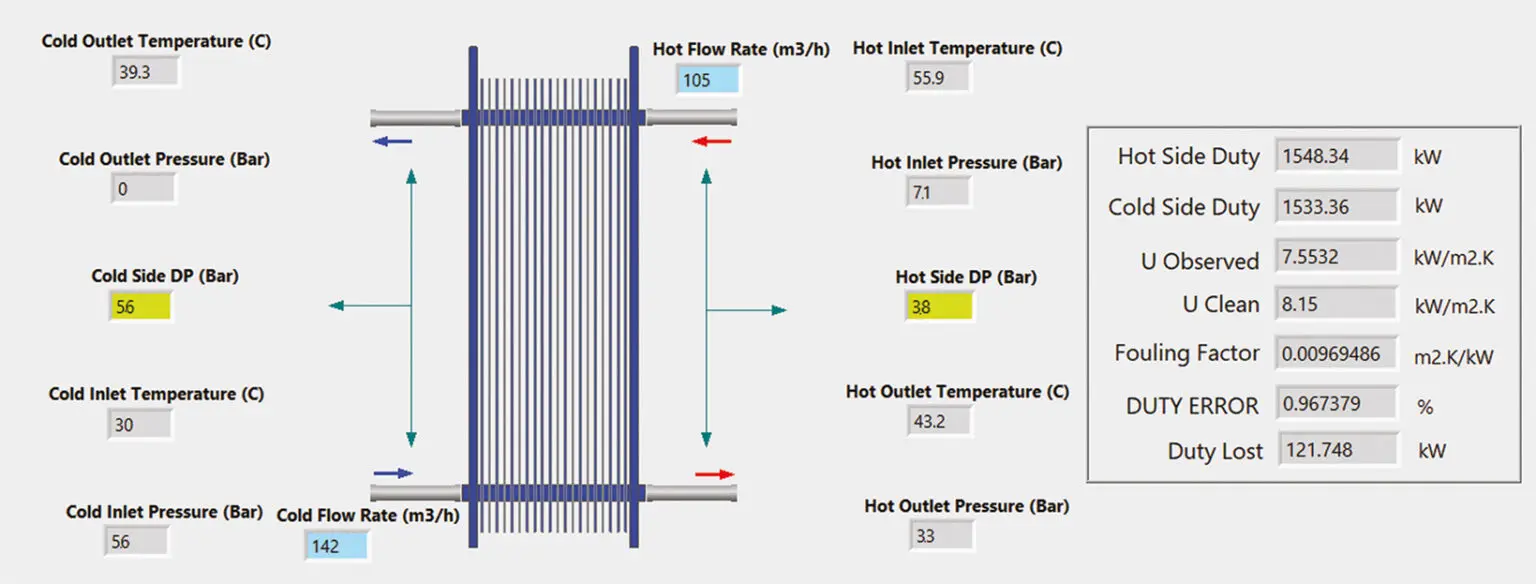

TIP ®

Taha intelligence platform

TGT has designed a real-time monitoring system to monitor the status of the plate heat exchangers via local network or the online web. The most important feature of this equipment is monitoring and analyzing the current status of heat exchangers including temperature, pressure and flow. TIP offers alarms and cleaning times to clients, which reduces maintenance costs. TIP provides users with a comprehensive range of information about their heat exchangers.