Heat Transfer Systems

Get to know other Heat Transfer products

What are heat transfers

TGT company have a decent amount of experience in thermal transfer and …

What are heat transfers

TGT company have a decent amount of experience in thermal transfer and heat exchange manufacturing due to the knowledge based on plate heat exchangers. Since the industry always require innovative solution for its problem, other products have been developed by our heat exchanger group in order to meet customers satisfaction.

Importance of optimization in heat transfer

Many industries such as petrochemical companies possess a …

Importance of optimization in heat transfer

Many industries such as petrochemical companies possess a high-pressure coolant fluid for their compressors or boilers, some cases even have fluids more than 800 Celsius temperature. Our conventional plate heat exchangers may not be suitable for these applications, therefore, other heat transfer solutions like Shell and Tubes, Recuperator and Air-coolers will come in handy. By optimizing a heat transfer device based on the customer application maximum efficiency will be achieved.

TGT variety of solutions

There are total of four other heat exchangers presented …

TGT variety of solutions

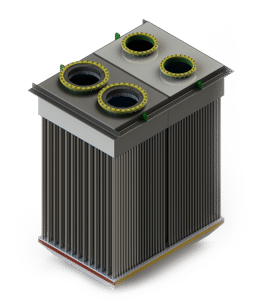

There are total of four other heat exchangers presented my TGT company for thermal transfer challenges. They are categorized based on stream types and maximum endurable pressure by the heat exchangers. These four heat exchangers are Recuperator, Shell and Tubes, Taha-Media and Air Coolers. Shell-and-tube heat exchangers can be used for extreme pressures and temperatures and accommodate both gas and fluid streams, while in recuperator, only gas media can be used for cold and hot streams. On the other hand, in Air-coolers and Taha-Media only a single process fluid will be processed on with the means of atmosphere air.

Explore and compare

Recuperator

Suitable for gas-to-gas fluids with connected pipe for increasing the surface area.

Suitable for heat recovery from hot air or gas and categorized based on fluid flow direction.

Max design temp

600°C

Max design pressure

25bar

Shell & Tube

Suitable for liquid streams with high design pressures.

With having the advantage of thick layer of shell outside and tubes inside, this heat exchanger has been used for long period of time for high flow rate and pressure and temperature.

Max design temp

500°C

Max design pressure

5bar

Taha Media®

An evaporation-based heat exchangers that is used to cool the incoming air from gas turbines.

These stems use special cellulose pads with water spraying system to exchange heat and mass between water and air.

Max design temp

Ambient air temp.

Max design pressure

Ambient air temp.

Air Cooler

In case of having only one liquid to be cooled.

Air coolers are used usually in case of using ambient air as coolant by using two configurations of fans installed.

Max design temp

200°C

Max design pressure

100bar

Why TGT is the best place for your Heat Transfer solutions

Fast response and delivery time

One of the main advantages of fully domestic production of TGT company's products is the accuracy and flaw less control over production line. With the means of automation and humane resources the fastest production record in Middle East is achieved.

Complete in-house production cycle

TGT stands as the sole company in Iran that encompasses the entire production cycle of Heat Transfer from start to customer delivery within a single facility.

Innovative optimized product and solutions

TGT Company, based on the indigenous knowledge developed within the company, has been able to develop a specialized software for designing various types of PHEs for the first time in the Middle East, placing it alongside the world's pioneers in this field.

On-call 24/7 support and service

In response to the critical needs of industries, TGT has established the Middle East's largest specialized center for heat transfer support, maintenance, and repair.