Brazed PHE

Brazed PHE

Plate Heat Exchanger (PHEs)

Function

How It Works

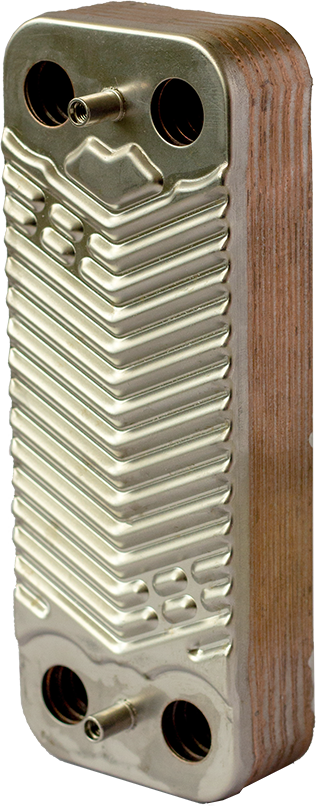

Brazed plate heat exchangers (BPHEs) evolved from traditional gasket plate heat exchangers to meet the demand for compact heat exchangers capable of handling high pressures and temperatures. Unlike gasket plate exchangers, BPHEs do not rely on gaskets. Instead, the stainless steel plates are brazed together in a vacuum furnace, creating a robust, leak-tight unit. Two fluids flow through separate channels within the plates, transferring heat efficiently. The compact design allows for easy installation without the need for brackets or foundations.

Specifications

Materials and Construction

BPHEs are primarily constructed from:

- Stainless steel plates: Typically AISI 316L

- Filler metal: Copper

The plates are pressed into a corrugated shape and then brazed together in a vacuum furnace. The brazing process creates a strong, leak-tight bond between the plates.

Product features

Design and Innovation

TGT utilizes advanced vacuum brazing technology to produce high-quality BPHEs. The vacuum brazing process ensures that the joints between the plates are clean and free of contaminants, resulting in optimal heat transfer and a long service life. TGT’s engineering team has optimized the design of BPHEs to maximize thermal efficiency and minimize pressure drop.

Competitive Advantages

TGT Competitive Edge

TGT offers several competitive advantages in the BPHE market:

- Advanced manufacturing: TGT employs state-of-the-art vacuum brazing technology to produce high-quality BPHEs.

- Customizable designs: TGT can tailor BPHEs to meet specific customer requirements.

- Compact design: TGT’s BPHEs are compact and lightweight, making them ideal for space-constrained applications.

- High thermal efficiency: Optimized plate design and brazing process for maximum heat transfer.

- Long service life: Robust construction and high-quality materials ensure long-term reliability.

- Domestic production: TGT’s ability to manufacture BPHEs locally reduces lead times and costs.

TGT’s BPHEs offer numerous advantages over traditional heat exchangers, including:

- Higher thermal efficiency: The compact design and direct plate-to-plate contact maximize heat transfer.

- Lower fouling: The smooth surfaces and efficient fluid distribution minimize fouling.

- Lower pressure drop: The optimized flow channels reduce pumping power requirements.

- Versatility: BPHEs can be used in a wide range of applications, including heating, cooling, and refrigeration.