Gasketed PHE

Bringing efficiency

to heat exchanger.

A gasketed plate heat exchanger (GPHE) is a device used to transfer heat between two or more fluids streams (liquid or gas). It consists of thin, corrugated metal plates separated by gaskets and compressed within a frame. As fluids flow through the channels formed between the plates, heat is transferred from the hotter fluid to the colder one. The corrugated pattern on the plates increases the surface area for heat transfer and promotes turbulence in the fluid flow, enhancing efficiency.

Function

Different materials

for different applications.

One of the main factors that have a direct influence with the heat transfer rate is the selection of the plates material. The choice of materials for these components is crucial for optimal performance and longevity. By understanding the properties and applications of different materials, engineers can design heat exchangers that are optimized for specific process requirements.

Some of the main materials that were implemented are such as: Stainless steels (304L, 316L & …), SMO, Titanium alloys.

Specifications

Plates

The plates in a PHE are typically made from corrosion-resistant metals.

Plates

The plates in a plate heat exchanger are typically made from corrosion-resistant metals. The specific metal used depends on the fluids being processed and the operating conditions. Common materials include:

Plate Material | Typical Applications |

AISI 304L | General purpose, very dilute chloride water, food products |

AISI 316L | General purpose, water, cooling tower water, dilute chloride solutions, food and dairy products, pharmaceutical media, dilute acids, dilute caustic solutions |

254 SMO / 904L | Brackish water, chloride solutions, dilute acids, dilute caustic solutions |

Titanium | Sea or brackish water, concentrated chloride solutions, chlorinated brines, dilute acids |

Titanium-palladium alloy | High temperature seawater or chlorinated brines |

Nickel 200/201 | Caustic solutions |

Nickel alloys (e.g. HASTELLOY C-276, C-2000, HYBRID-BC1) | Corrosive environments (e.g. concentrated sulfuric acids), chemical processing |

Gaskets

Gaskets play a vital role in sealing the fluid channels between the plates.

Gaskets

Gaskets play a vital role in sealing the fluid channels between the plates. The choice of gasket material depends on the fluid compatibility, temperature, and pressure. Common gasket materials and their applications are summarized in the following table:

Gasket Material | Operating Temperature | Applications |

SBR | -15 to 70°C | Water |

NBR | -18 to 100°C | Water, mineral oil-based fluids, fats, vegetable and animal oils, silicone oil |

NBRLT | -45 to 100°C | |

HNBR | -24 to 150°C | Crude oil, water, mineral oil-based fluids, fats, vegetable and animal oils, silicone oil |

EPM/EPDM | -50 to 150°C | Water, saturated steam, alcohols, organic and inorganic acids, polar solvents, alkaline environments |

Viton | -18 to 200°C | Fats and mineral oils, aromatic and chlorinated hydrocarbons, petroleum, acids |

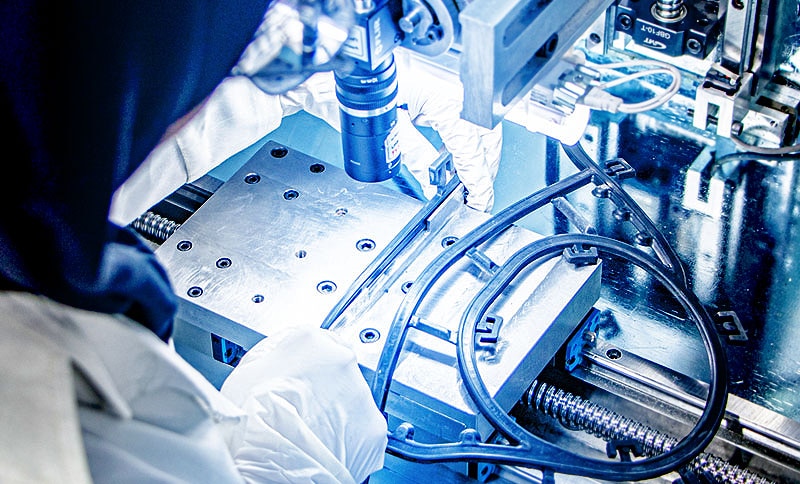

Design and innovation

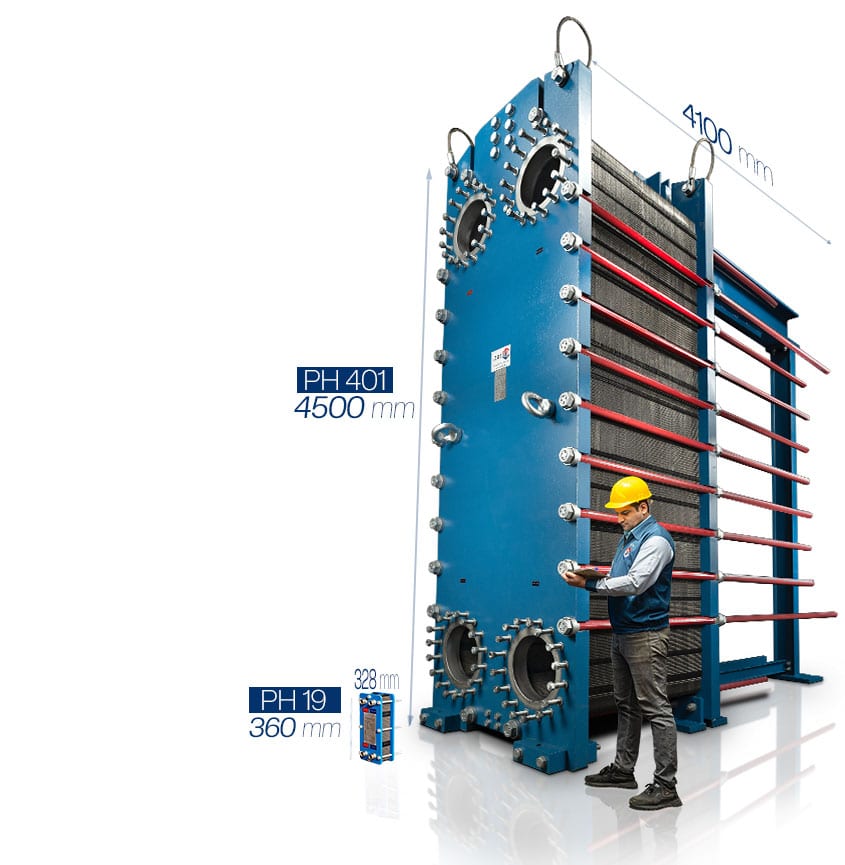

TGT, a leading manufacturer of GPHEs, offers a wide range of products designed to meet various industrial needs. The company utilizes advanced software for precise design and optimization. TGT’s products are manufactured using high-quality materials and state-of-the-art equipment, ensuring superior performance and durability. The company also boasts a large-scale hydraulic press, allowing for the production of large-format heat exchangers.

Product Features

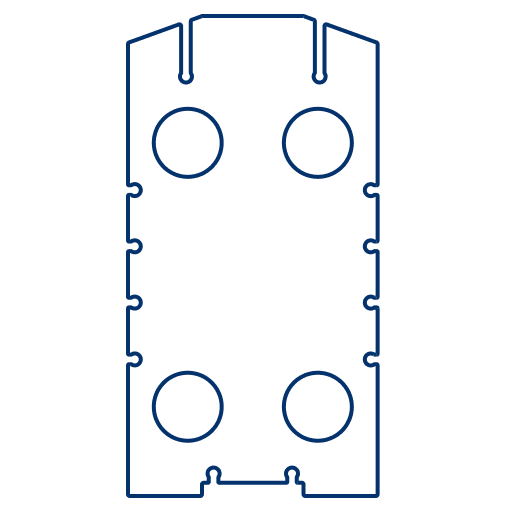

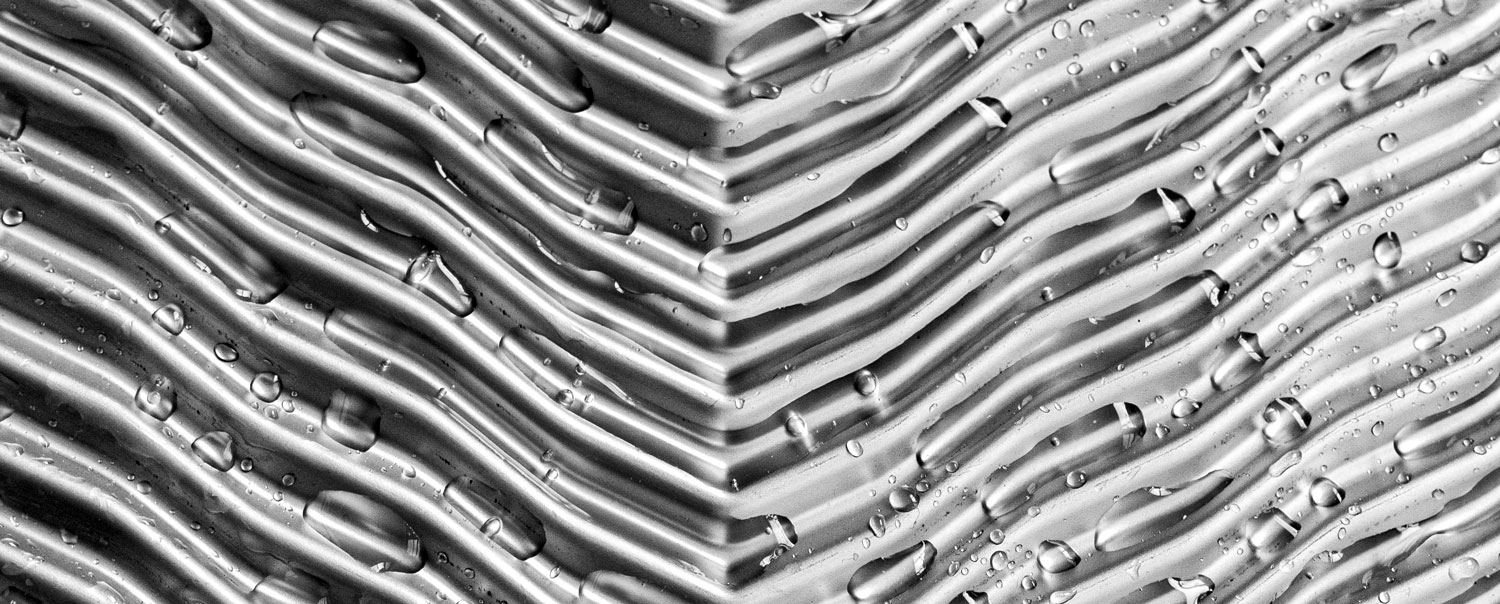

Plate Design

The science behind our plates

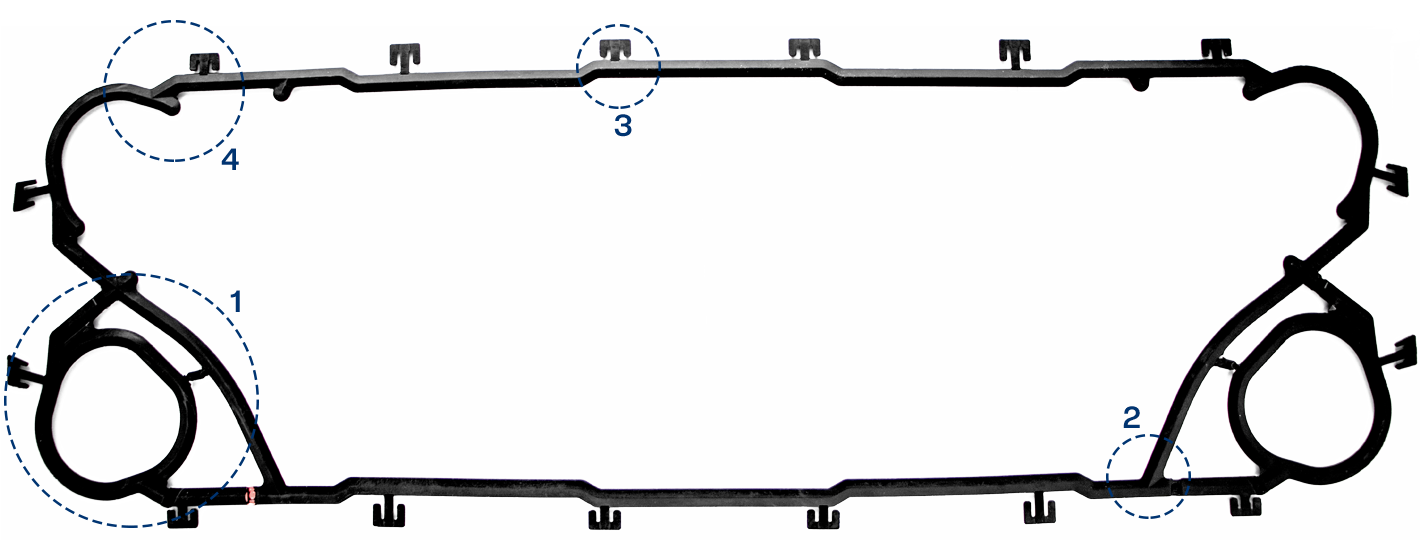

Suspension Groove to Guide Bar

Leak Chamber

Inlet / Outlet

in order to decrease port pressure drop, inlet/outlet

portholes are optimized

Main Heat Transfer Area

To increase fluid turbulency and heat

transfer coefficient. Broken chevron has

been designed and patented

Gasket Installed in Plate Groove

In order to seal plates correctly, TGT gaskets

are uniquely designed and manufactured. It results in

easy maintenance, less cost and higher operation pressure.

Distribution Area

The TGT plate patterns distribution area makes

flow pass the entire plate more uniform

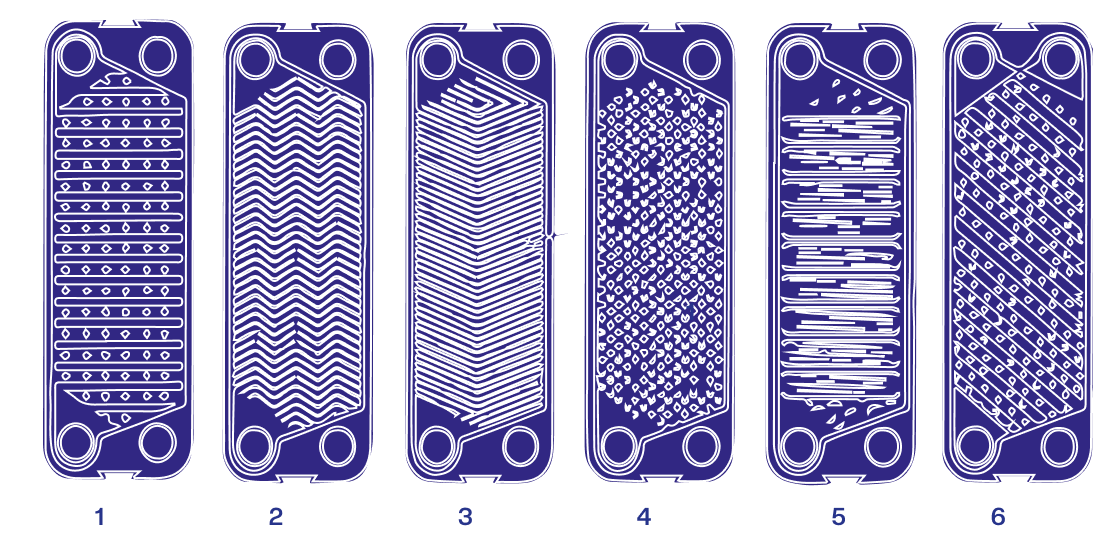

Plate Types

Washboard

This pattern resembles a washboard, with a series of raised ridges and valleys.

Chevron or Herringbone

This pattern is characterized by a V-shaped or herringbone pattern.

Washboard with Secondary Corrugations

This pattern is a variation of the washboard pattern, with additional smaller corrugations.

Zigzag

As the name suggests, this pattern consists of a series of zigzag lines or folds.

Protrusions and Depressions

This pattern features raised protrusions and corresponding depressions.

Oblique Washboard

This pattern is a washboard pattern that is oriented at an angle to the main flow direction.

Gasket Features

Our gaskets are engineered with a unique oval profile that perfectly complements TGT’s specialized plates, maximizing heat transfer efficiency.

The updated gasket profile guarantees an exceptional seal, preventing leaks and ensuring optimal performance.

Our proprietary gasket formulation delivers exceptional performance at elevated temperatures and pressures, exceeding industry standards.

TGT’s innovative gasket design minimizes the risk of leaks and simplifies the assembly process, saving you time and effort.

Gasket Types

To ensure optimal performance in a wide range of applications, TGT offers a variety of gasket materials. The choice of gasket material depends on the specific fluid being handled, temperature, and pressure conditions.

PHE Sizes

What makes us different?

TGT Advantages

Design

Complete PHE design

TGT takes a holistic approach to the design and manufacturing of its gasketed plate heat exchangers. By designing every component in-house, from the intricate plate patterns to the robust frame assemblies, TGT ensures optimal performance and reliability. This level of control allows for precise customization to meet specific process requirements, such as pasteurization and homogenization of dairy products and beverages.

Patented desgin features

Patented Adhesive

Taha-GLUE®: TGT’s patented, chlorine-free adhesive prevents HE corrosion.

Patented Gaskets

TGT Gaskets: Enhanced profile, superior seal, leak-free performance.

Patented Plates

TGT’s patented GPHE plates: Enhanced design, optimized performance.

Optimized PHE design software

One of the most critical technical areas in the production of PHEs is the ability to simulate processes and design these exchangers accurately and efficiently. Currently, this capability is limited to a few countries. It is essential to note that the wrong choice of a PHE and an inaccurate or inefficient design, due to the use of unsuitable software or inaccurate calculations, can lead to increased costs, production disruptions, and even collateral damage – if there is a hazardous fluid in the exchanger. TGT Company, based on the indigenous knowledge developed within the company, has been able to develop a specialized software for designing various types of PHEs for the first time in the Middle East, placing it alongside the world’s pioneers in this field.

R&D publications

Manufacturing and Quality

Full GPHE production cycle

TGT maintains complete control over the entire GPHE production cycle. From initial design to final assembly, all components are engineered in-house, ensuring optimal performance and customization. This comprehensive approach allows for precise tailoring of heat exchangers to specific process requirements.

In-house gasket manufacturing

TGT stands as the sole company in middle east that encompasses the entire production cycle of plate heat exchangers from start to finish within a single facility. This comprehensive approach encompasses every stage of the manufacturing process, including: procurement of raw materials, engineering design of the heat exchanger, design of plate and gasket molds, mold manufacturing, plate forming, gasket production, frame production,Laser welding,Automated quality control, assembly and performance testing. In-house manufacturing of PHEs at TGT, coupled with earning customer trust and safeguarding their intellectual property, enables the delivery of products tailored to the precise and even specific needs of each customer. Moreover, this approach empowers TGT to assume full responsibility for the quality and performance of its products, ensuring unwavering customer satisfaction.

Strict quality control

TGT’s manufacturing process, from raw material sourcing to final assembly, is rigorously controlled by a dedicated quality assurance team. Every step, including plate forming, machining, painting, and assembly, is monitored to ensure adherence to the highest quality standards.

Advanced inspection techniques, such as darkroom checks for plate dimensions and form, and cutting-edge tests for gasket hardness and sealing, are employed to meet global quality benchmarks.

ISO 17025 certified laboratories

Heat exchanger performance laboratory

Heat exchanger performance laboratory

During the designing and manufacturing of a plate heat exchanger, after numerical analysis and designing a new product (new design of plates and gasket), a prototype is manufactured and the performance is tested under actual operating conditions. TGT has established a one-of-a-kind industrial research-based laboratory for testing the performance and energy efficiency of heat exchangers. TGT’s heat exchanger laboratory is the only heat exchanger performance laboratory in the country to be certified with ISO 17025.

Polymer and rubber laboratory

Polymer and rubber laboratory

TGT’s specialized polymer and rubber laboratory is established to control the quality parameters and also expand the variety of polymer products in the oil, gas, and petrochemical industries. This laboratory has gained the ISO 17025 certificate by taking advantage of faculty members, expert engineers, and advanced testing devices based on national and international standards including the most practical tests of the polymer and rubber industries. The laboratory has special equipment to determine the life of PHE gaskets in order to improve their lifetime.

Metallography and non-destructive testing laboratory

Metallography and non-destructive testing laboratory

Different types of manufacturing processes like machining, welding, cladding required metallography and microscopic examining to achieve the desired properties of alloys and metals such as toughness, hardness, and tensile strength. To ensure the quality of manufactured parts, non-destructive testing is inevitable. For this purpose, the metallography and non-destructive testing (NDT) laboratory has been equipped and can perform different metallography and non-destructive testing services. This laboratory has also received the ISO 17025 certificate because of its specialized expertise and equipment.

Delivery Time

Industrial facilities with critical heat exchanger issues facing unexpected outages can suffer massive daily losses, often exceeding millions of dollars. Due to the time sensitivity in the operation of the units, we are the fastest in the Middle East due to having a complete production cycle.

One of the main advantages of fully domestic production of TGT company’s products is the accurate and fast control of the production cycle, the main advantage of which is the fast and automated production of products. This is not possible without having a unified project management system.

Service (24/7)

The largest specialized heat exchanger repair center in the Middle East

TGT repair and maintenance service center is the largest specialized center for repairing heat exchangers in the country. Expert engineers can disassemble, repair, recondition and clean gasketed, semi-welded, and welded heat exchangers on our service center sites. Technical experts initially check all parts of the plate heat exchanger. After that the damaged parts are immediately replaced with new parts, the assembled heat exchanger is tested by hydrostatic testing equipment according to API 662 or other standards. After testing, our service technicians prepare the PHEs for packing, loading, and shipping to the destination.