Air cooler

Air cooler

Heat Transfer System (ACHEs)

Function

How It Works

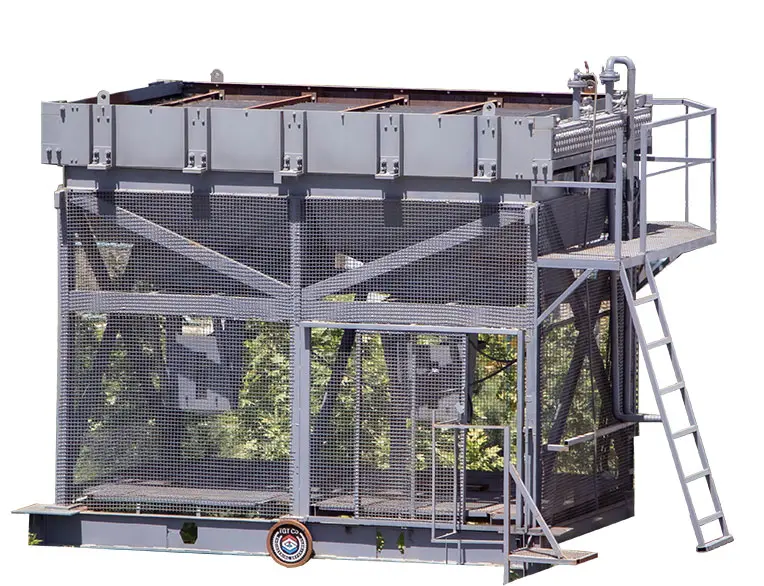

Air-cooled heat exchangers (ACHEs) are thermal devices that dissipate heat from a process fluid to the ambient air using fans. This design eliminates the need for water as a coolant, reducing operational costs and environmental impact.

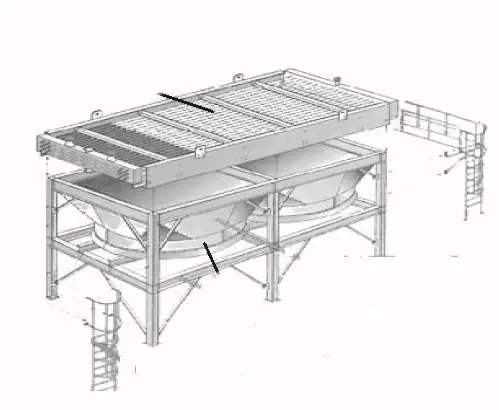

How it works: ACHEs can operate in two primary modes: forced draft and induced draft. In forced draft, fans are positioned below the tube bundle, forcing air upwards through the tubes. In induced draft, fans are placed above the tube bundle, pulling air downward.

Types of ACHEs

- Horizontal: The tube bundle is arranged horizontally, with air flowing vertically.

- Vertical: The tube bundle is vertical, and air flows horizontally.

- V-type: The tube bundle is inclined, with air flowing in a V-shaped pattern.

- A-type: Similar to the V-type, but with a different tube bundle arrangement.

Key components of ACHEs:

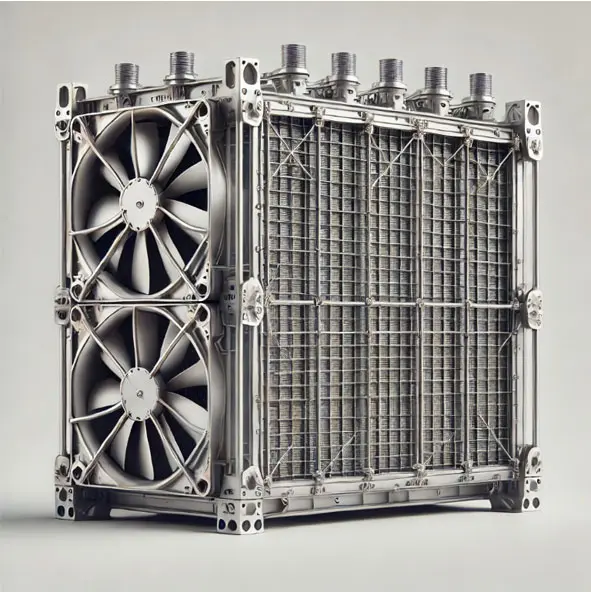

- Finned tubes: Enhance heat transfer surface area.

- Headers: Distribute the process fluid to and from the tubes.

- Fans: Force or induce airflow across the tube bundle.

Advantages of ACHEs:

- No need for water

- Lower operating costs

- Reduced fouling compared to water-cooled systems

- Easy access to abundant and free cooling medium (air)

- Simple installation and low maintenance

- Environmentally friendly

Specifications

Materials and Construction

ACHEs are typically constructed using materials such as:

- Carbon steel

- Stainless steel

- Copper

- Copper nickel alloys

The choice of materials depends on factors like corrosion resistance, temperature, and pressure.

Product features

Design and Innovation

TGT has introduced innovative features in its ACHEs, such as:

- Taha Payam Monitoring System: This intelligent system monitors key parameters, provides real-time data analysis, and offers predictive maintenance capabilities.

- Optimized heat transfer design: TGT’s designs maximize heat transfer efficiency.

- Advanced manufacturing techniques: TGT employs state-of-the-art manufacturing processes to ensure product quality.

Competitive Advantages

TGT Competitive Edge

TGT offers several competitive advantages in the ACHE market:

• Water conservation: TGT’s ACHEs address the growing global water scarcity issue.

• Cost-effective: Reduced operating costs due to the elimination of water treatment and pumping systems.

• Environmental friendliness: Minimized environmental impact.

• Customization: TGT offers customized solutions to meet specific customer requirements.

• Advanced technology: TGT leverages the latest technologies to enhance product performance and reliability.

• Quality assurance: Rigorous quality control measures ensure consistent product quality.

In conclusion, TGT’s air-cooled heat exchangers offer a sustainable and efficient solution for heat transfer applications. With their innovative design, advanced manufacturing processes, and commitment to quality, TGT’s ACHEs are well-suited for various industries, including oil and gas, petrochemicals, power generation, and food processing.