Shell & Tube

Shell & Tube

Heat Transfer System

Function

How It Works

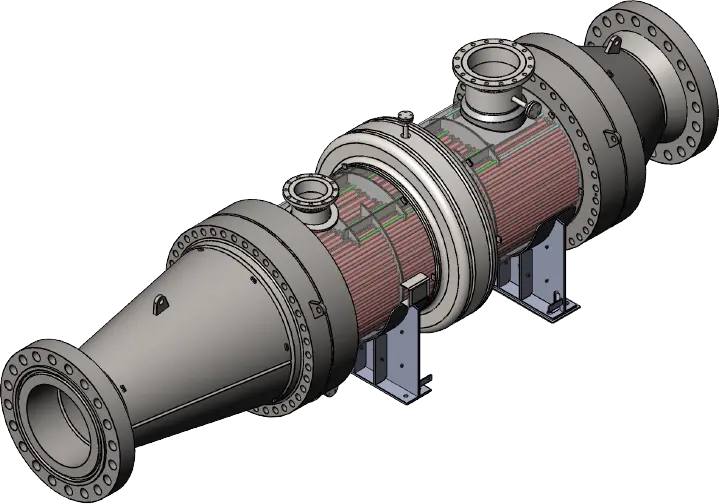

A shell-and-tube heat exchanger is one of the most widely used heat transfer devices in industry. Its versatility and ability to operate under a wide range of pressures make it a preferred choice for numerous applications. In a shell-and-tube heat exchanger, one fluid flows through tubes while another fluid flows over the tubes and through the shell. Heat transfer occurs through the tube walls, without the two fluids coming into direct contact. This configuration allows for efficient heat exchange between the two fluids.

Key advantages

Key advantages of shell-and-tube heat exchangers include:

- High thermal efficiency: Effective heat transfer between fluids.

- Ability to withstand high pressures and temperatures.

- Low pressure drop: Minimizes energy losses.

- Suitable for a wide range of applications.

- Low fouling rates: Reduces maintenance requirements.

- Simple design and flexibility: Can be customized for various process requirements.

- Suitable for corrosive fluids.

- Easy maintenance and repair.

- Long service life and durability.

Applications

Shell-and-tube heat exchangers find applications in:

- Oil and gas industries

- Refineries and petrochemical plants

- Power plants

- Food and beverage processing

- HVAC systems

Specifications

Materials and Construction

The components of a shell-and-tube heat exchanger and their typical materials are:

- Shell: Carbon Steel, AISI 304L, AISI 316L

- Head: Carbon Steel, AISI 304L, AISI 316L

- Tubes: Carbon Steel, AISI 304L, AISI 316L, Copper, Copper Nickel

Product features

Design and Innovation

TGT has made significant advancements in shell-and-tube heat exchanger design and manufacturing. A notable innovation is the use of orbital welding for joining tubes, which enhances quality and efficiency.

Competitive Advantages

TGT Competitive Edge

TGT leverages the latest technologies, high-quality materials, and rigorous quality control to produce superior shell-and-tube heat exchangers. By adhering to international standards and conducting comprehensive testing in specialized laboratories, TGT ensures that its products meet the highest quality standards. TGT’s in-house design and manufacturing capabilities allow for complete control over the production process, resulting in consistent product quality. Additionally, TGT’s shell-and-tube heat exchangers offer excellent durability, ease of maintenance, and a wide operating pressure range.