Options

Explore HTS

Options

HTS Accessories

HTS Spare parts

Explore separation

Options

separation Accessories

separation Spare parts

Explore Rotary Equipment

Options

Rotary Equipment Accessories

Rotary Equipment Spare parts

Explore Pelletizing

Options

Pelletizing Accessories

Pelletizing Spare parts

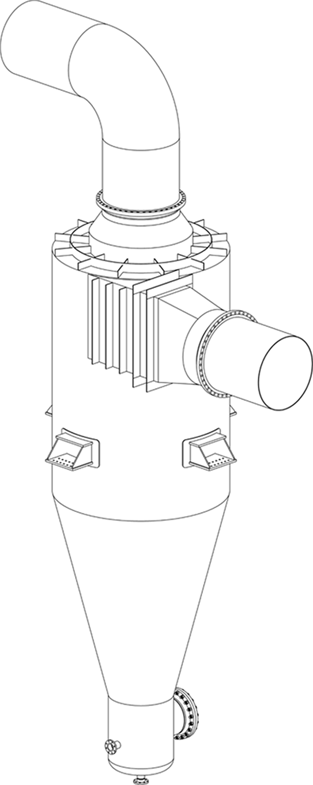

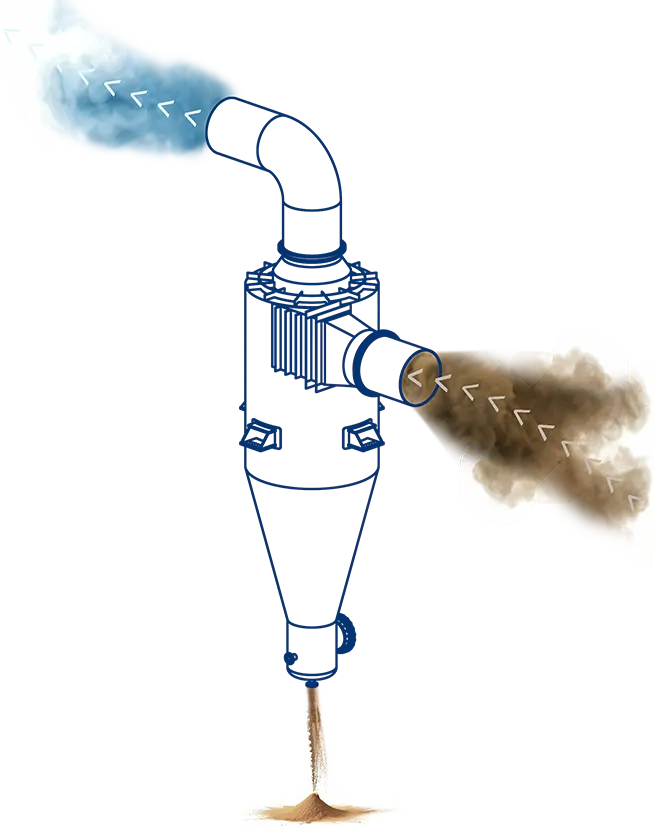

Cyclone separators are designed to remove larger particles and droplets from a gas stream. They operate on the principle of centrifugal force, created by the spinning motion of the gas. The heavier particles and droplets, due to their greater inertia, are forced towards the outer wall of the cyclone and then fall into a collection zone. This type of separator is characterized by its simple design and lack of moving parts, resulting in lower manufacturing, maintenance, and operating costs.

A cyclone is essentially a vessel with a specific geometry designed to separate fluid phases. The commonly used materials for the vessel are carbon steels such as A516 Gr. 70. The manufacturing process involves rolling, dished head forming, and welding.

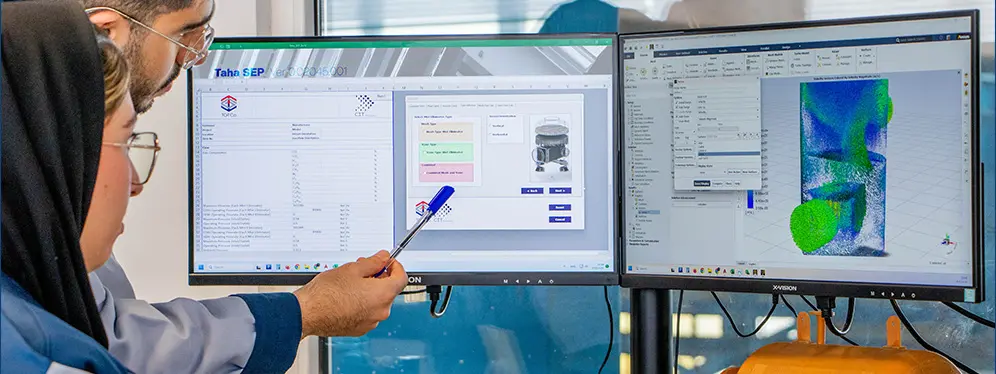

Our cyclone designs are optimized using the proprietary software Taha-sep, developed specifically for this purpose at TGT. This software enables us to perform detailed simulations and analyses to ensure optimal performance.

Customized Design: Each project and customer receives a unique, tailored design that aligns with their specific requirements.

Optimized Performance: Our cyclone separators are engineered to minimize size, weight, pressure drop, and fouling while maintaining high separation efficiency. This leads to reduced initial and operational costs.

Advanced Simulation: We utilize advanced engineering software like Ansys to simulate the performance of our cyclones, ensuring accurate design and optimization.

Adherence to Standards: Our designs comply with recognized industry standards such as ASME Section VII.