Mesh Type

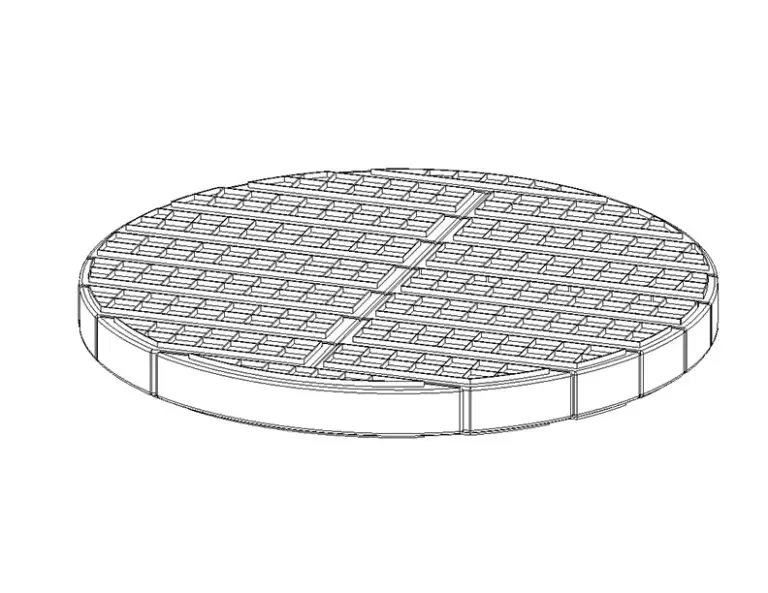

Mesh type

Industrial Mist Eliminator

Function

How Mesh Type Mist Eliminators Work

Mesh-type mist eliminators consist of multiple layers of interwoven wires that create a porous medium. As a gas passes through this porous medium, the wires act as random obstacles, causing the entrained liquid droplets to collide with and adhere to the wire surfaces. This process effectively separates the liquid droplets from the gas stream.

Specifications

Materials and Construction

Materials: Both the vanes and frames are constructed from various grades of stainless steel (304 and 316) to ensure corrosion resistance and extended product life.

Manufacturing Processes: Laser cutting, CNC bending, argon welding, and spot welding are employed in the manufacturing process.

Product features

Design and Innovation

Customized Design: Each project and customer receives a unique, tailored design that aligns with their specific needs.

Optimized Performance: Our mist eliminators are optimized to reduce size, weight (lowering initial costs), pressure drop, and fouling (reducing operational costs) while maintaining high efficiency.

Proprietary Design Software (Taha-Sep): Our engineering team utilizes the proprietary Taha-Sep software for the exclusive and custom design of industrial mist eliminators. Based on process parameters such as temperature, pressure, maximum flow rate, allowable pressure drop, gas-to-liquid ratio, and required separation efficiency, we perform detailed design and sizing.

Our designs are grounded in computational fluid dynamics (CFD) simulations, experimental validation, and adherence to industry standards (API, ASME, IPS, and GPSA) to ensure optimal efficiency and pressure drop.

Competitive Advantages

Design and Innovation

Customized Design: Each project and customer receives a unique, tailored design that aligns with their specific needs.

Optimized Performance: Our mist eliminators are optimized to reduce size, weight (lowering initial costs), pressure drop, and fouling (reducing operational costs) while maintaining high efficiency.

Proprietary Design Software (Taha-Sep): Our engineering team utilizes the proprietary Taha-Sep software for the exclusive and custom design of industrial mist eliminators. Based on process parameters such as temperature, pressure, maximum flow rate, allowable pressure drop, gas-to-liquid ratio, and required separation efficiency, we perform detailed design and sizing.

Our designs are grounded in computational fluid dynamics (CFD) simulations, experimental validation, and adherence to industry standards (API, ASME, IPS, and GPSA) to ensure optimal efficiency and pressure drop.