Rotary shafts

Rotary Shaft Refurbishment

For Gas turbines

Function

How It Works and operation

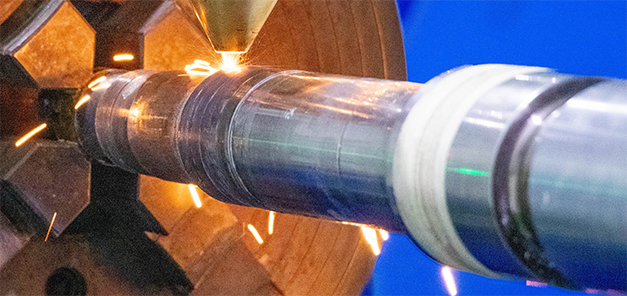

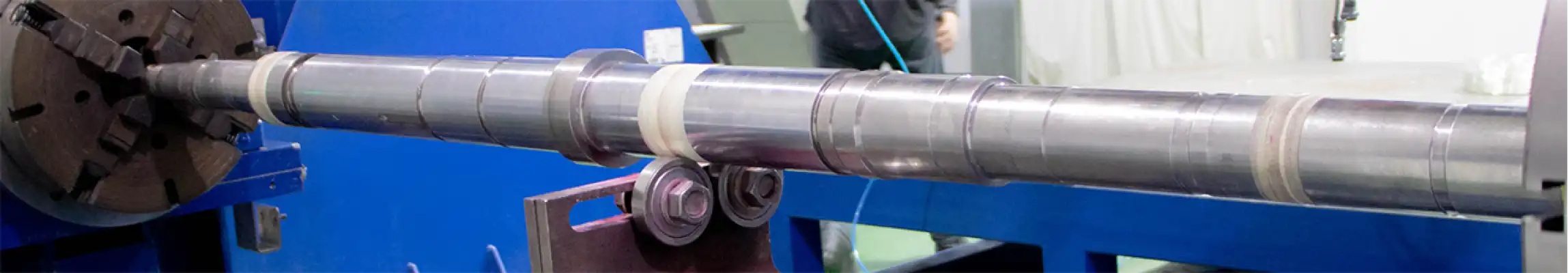

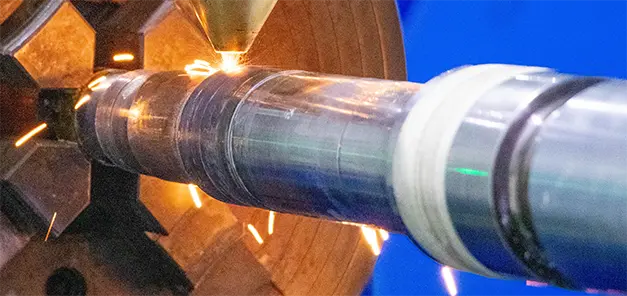

Gas turbine rotary shafts are vital components that transmit rotational energy between the turbine and other system elements. Over time, these shafts are subjected to extreme stresses, high temperatures, and corrosive environments, which can lead to wear, surface damage, and fatigue. The refurbishment process restores the shaft’s functionality and extends its service life using advanced techniques such as laser cladding, hard facing, and precision machining. These methods repair worn or damaged areas while maintaining the shaft’s mechanical integrity. The process involves applying metallurgically bonded materials to the worn sections and performing post-cladding heat treatment to enhance durability and performance.

Specifications

Materials and Construction

Gas turbine rotary shafts are vital components that transmit rotational energy between the turbine and other system elements. Over time, these shafts are subjected to extreme stresses, high temperatures, and corrosive environments, which can lead to wear, surface damage, and fatigue. The refurbishment process restores the shaft’s functionality and extends its service life using advanced techniques such as laser cladding, hard facing, and precision machining. These methods repair worn or damaged areas while maintaining the shaft’s mechanical integrity. The process involves applying metallurgically bonded materials to the worn sections and performing post-cladding heat treatment to enhance durability and performance.

Product features

Design and Innovation

TGT employs state-of-the-art laser cladding technology, which ensures minimal heat input, reducing distortion and maintaining the shaft’s dimensional accuracy. This method produces a metallurgical bond with low dilution rates, enhancing the repaired section’s durability. Advanced CNC grinding and polishing techniques restore the shaft’s surface finish and geometric tolerances to within 0.01 mm. Additionally, automated hard facing using robotic systems ensures uniform coating thickness and quality. The use of proprietary repair procedures guarantees that the refurbished shafts match or exceed their original performance, even under the most demanding conditions.

Competitive Advantages

Design and Innovation

TGT’s gas turbine rotary shaft refurbishment offers several key advantages over traditional repair methods. Laser cladding ensures high precision, minimal heat impact, and improved material bonding, resulting in superior durability and resistance to wear. The process is more cost-effective and environmentally friendly compared to replacing the entire shaft. Furthermore, TGT’s use of high-quality cladding materials and advanced machining ensures that the refurbished shafts deliver long-lasting performance and reliability. With reduced downtime and extended service life, TGT’s solutions are ideal for industries requiring dependable and efficient gas turbine operation. These competitive advantages make TGT a trusted partner for turbine shaft refurbishment in energy, aerospace, and industrial applications.